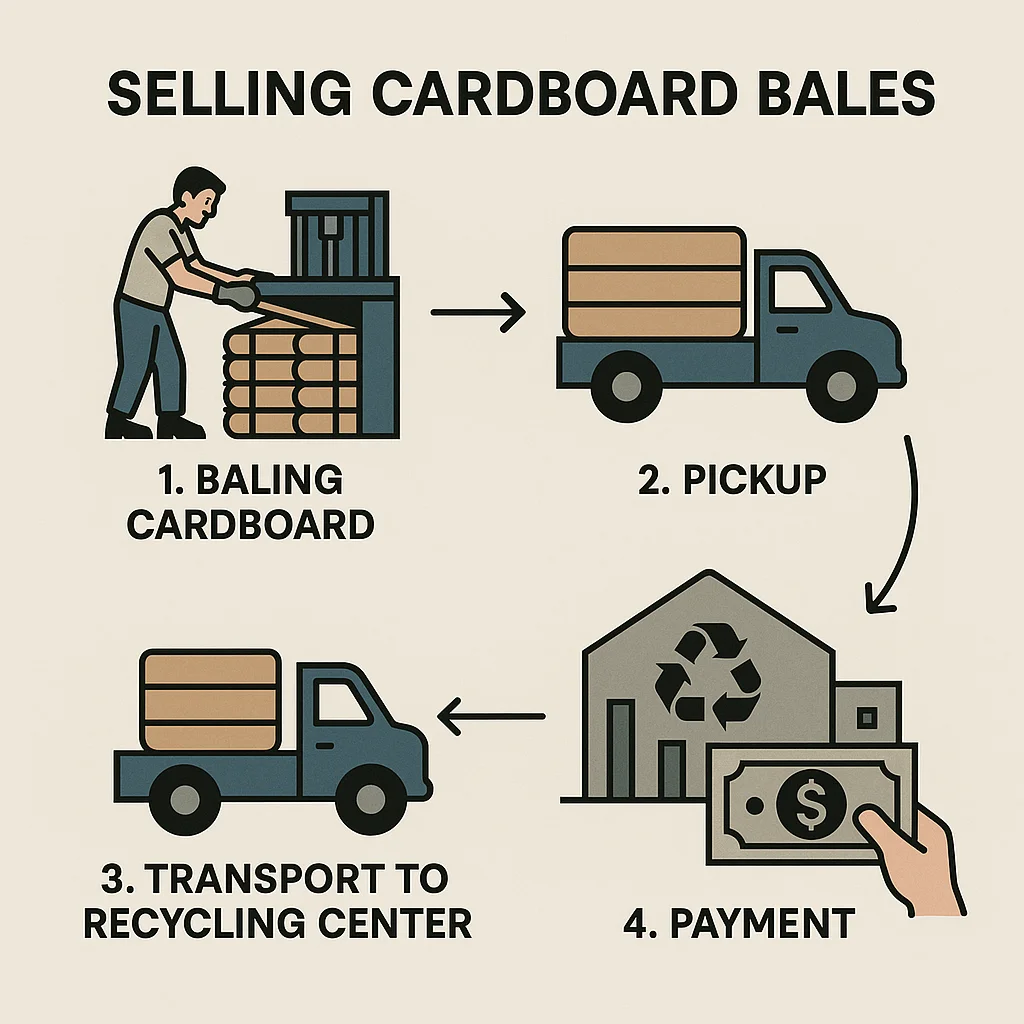

Key Takeaway: The most lucrative and convenient options for selling or recycling cardboard bales include local scrap yards and recycling centers, industrial paper mills, national brokers and consolidators, and specialized waste-hauling companies. Many of these buyers offer on-site pickup and pay competitive rates, often on a per-ton or per-pound basis. Building a reliable relationship with a consistent buyer will streamline logistics, maximize revenue, and ensure environmentally responsible processing of your cardboard bales.

(more…)Category: Cardboard

-

Maximizing Revenue from Cardboard Bales

Key Takeaway In today’s fluctuating recycling markets, sellers can expect to receive anywhere from $40 to $120 per ton of baled corrugated cardboard under typical conditions, with occasional extremes ranging from $20 up to $210 per ton based on regional demand, bale quality, and prevailing commodity prices. Achieving top-dollar requires producing mill‐size bales, maintaining high material quality, and timing sales to market peaks.

(more…) -

Maximizing Efficiency and Sustainability with Cardboard Balers

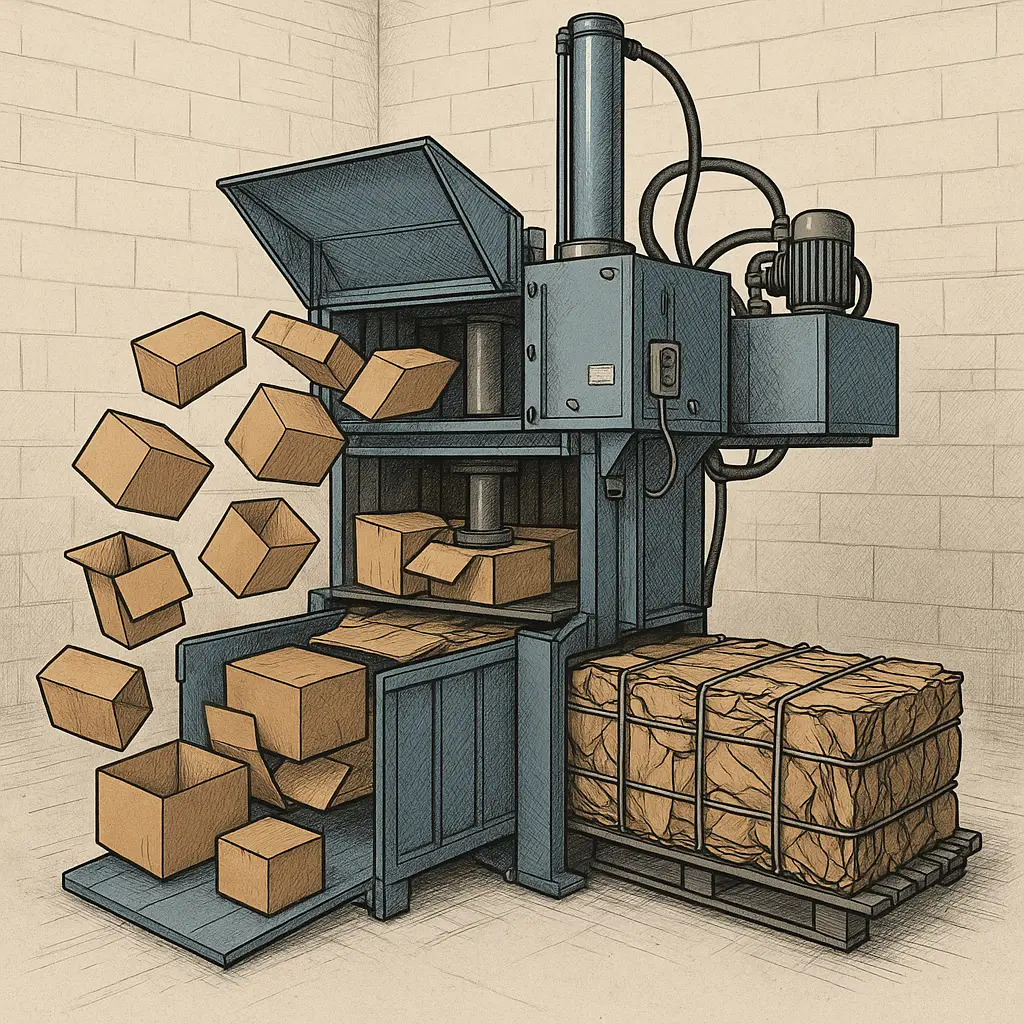

Key Takeaway: Investing in a cardboard baler transforms loose, bulky cardboard waste into compact, manageable bales—reducing storage costs by up to 80%, streamlining recycling processes, and supporting sustainable waste management practices.

(more…) -

Maximizing Revenue from Cardboard Bales: Buyers, Marketplaces, Pricing, and Best Practices

Turn Your Waste into Profit Businesses of all sizes generate substantial volumes of corrugated cardboard, an in-demand commodity whose value often goes untapped. By compressing loose cardboard into dense bales, you reduce handling and transport costs while creating a product that recyclers, paper mills, manufacturers, and waste brokers pay for. Understanding who buys cardboard bales, where to sell, how to prepare, and what prices to expect is essential to optimizing your revenue stream.

(more…) -

Guide to Selling and Recycling Cardboard Bales

Key Takeaway: The most lucrative and convenient options for selling or recycling cardboard bales include local scrap yards and recycling centers, industrial paper mills, national brokers and consolidators, and specialized waste-hauling companies. Many of these buyers offer on-site pickup and pay competitive rates, often on a per-ton or per-pound basis. Building a reliable relationship with a consistent buyer will streamline logistics, maximize revenue, and ensure environmentally responsible processing of your cardboard bales.

(more…) -

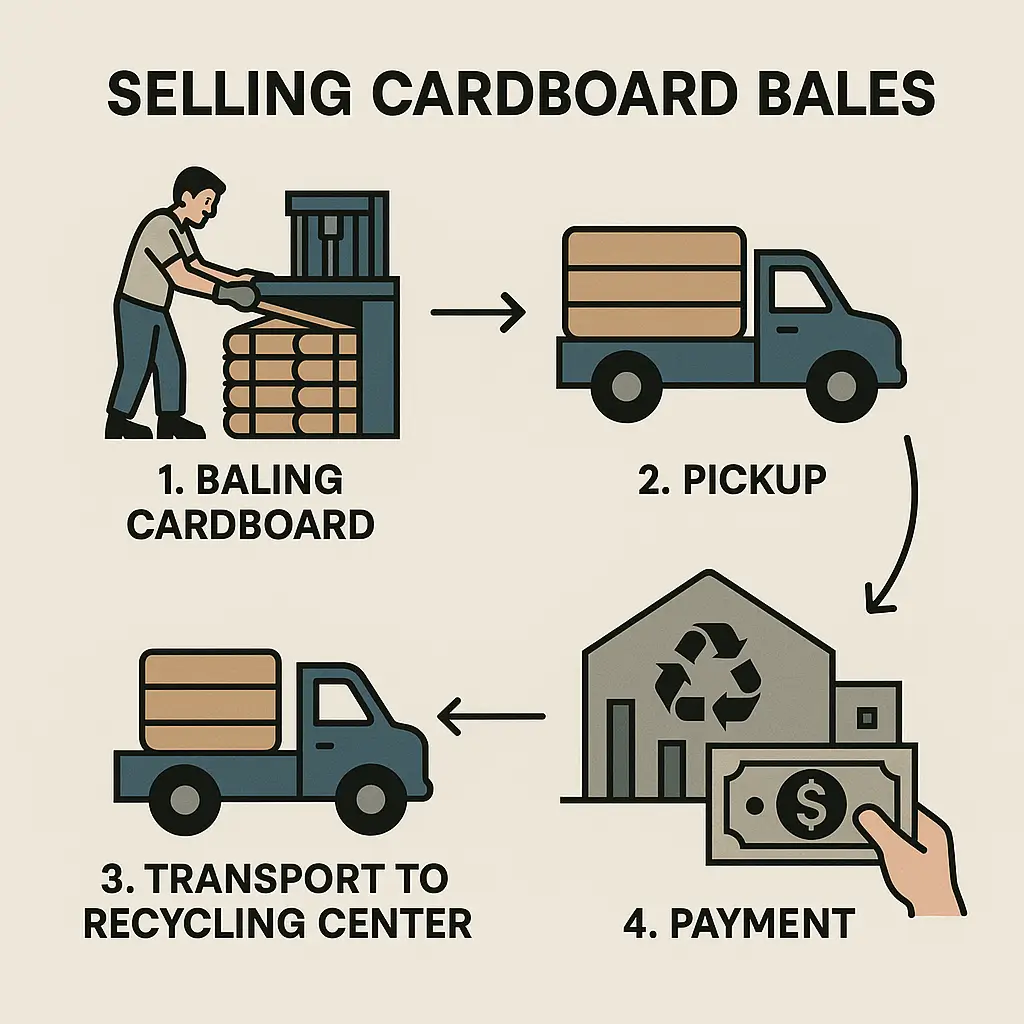

Optimizing Cardboard Baling: Materials, Limitations, and Contamination Risks

Efficient cardboard baling lies at the heart of sustainable waste management and recycling operations. A properly configured baler can process large volumes of corrugated cardboard into dense, transportable bales, reducing hauling costs and material footprint. However, maximizing the value and purity of cardboard bales requires careful attention to feedstock specifications, permissible materials, and contamination controls. The following sections examine:

(more…) -

Overview and Detailed Insights on Cardboard Baling

Key Takeaway: Cardboard baling is a critical step in the recycling chain that transforms loose cardboard into dense, transport-efficient bales. Leasing a baler typically ranges from $200 to $600 per month. Effectively describing baling experience on a resume can highlight operational skills, equipment maintenance, and environmental stewardship. While Jet Equipment does not manufacture cardboard balers, specialist vendors such as Bramidan, Kernic Systems, and Ken Mills Engineering supply a range of vertical, horizontal, and twin-ram balers with bale weights from 250 lbs to over 1,400 lbs.

(more…) -

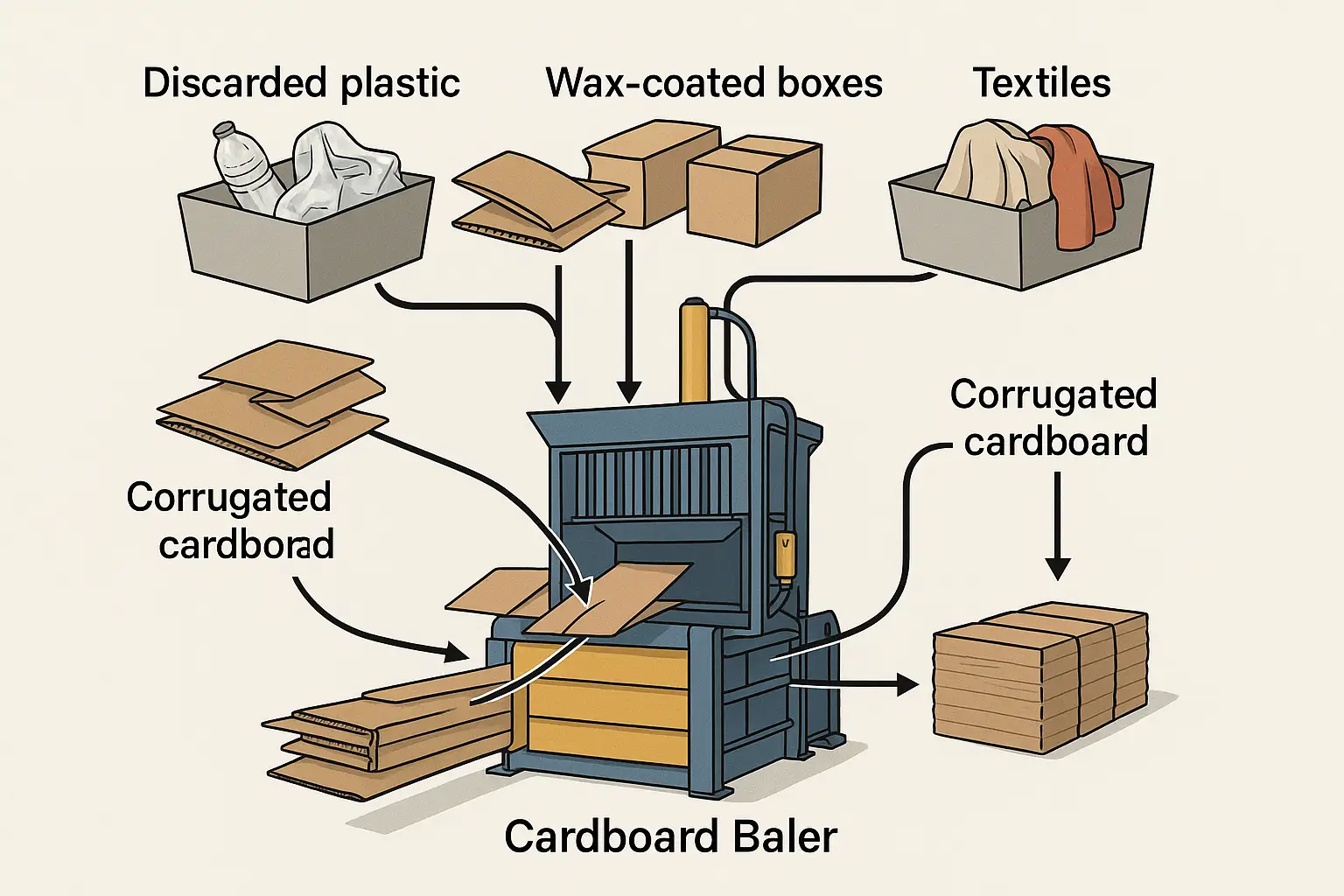

Cardboard Bales: Recycling, Crafting, and Handling Techniques

Key Takeaway: Cardboard bales, whether generated by retail giants like Walmart or repurposed into decorative “hay bales,” can be efficiently managed through established recycling and processing systems. Additionally, with the right tools and techniques, cardboard can be transformed into stable, upright structures resembling hay bales and safely unloaded from baling equipment such as the Harmony cardboard baler.

(more…) -

Understanding the Weight of a Cardboard Bale

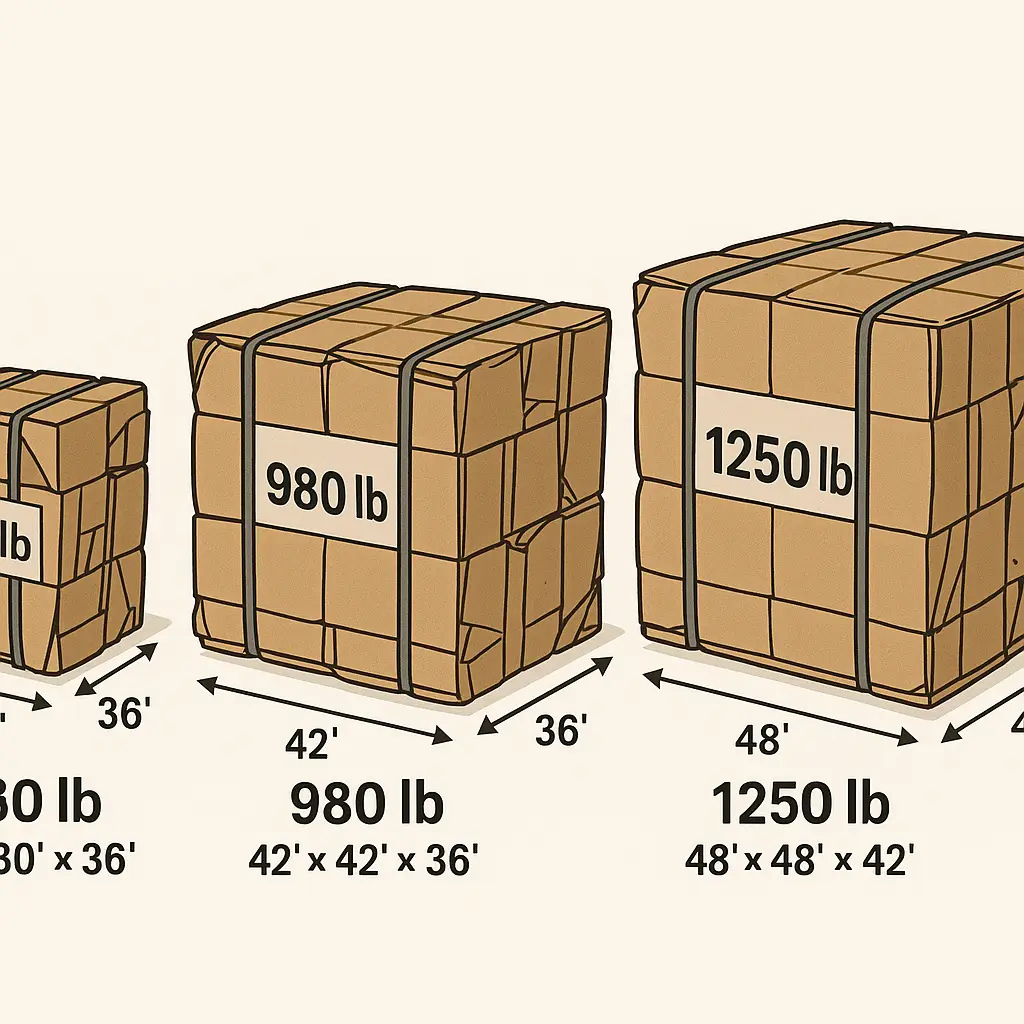

Key Takeaway: A cardboard bale can weigh anywhere from 100 lbs for small-office bales up to 1,500 lbs or more for heavy-duty mill-size bales. Typical medium-size bales produced by vertical balers average around 660 lbs (300 kg), while industrial mill-size bales often range between 800 lbs and 1,100 lbs. Variations in weight stem from bale dimensions, compression force, moisture content, and cardboard type.

(more…) -

Cardboard Bales: Legality, Store Economics, and Individual Opportunities

Key Takeaway: Businesses and individuals can legally and profitably engage in the baling and sale of cardboard—provided they comply with property and recycling regulations, invest in proper equipment to produce mill-sized bales, and partner with licensed recyclers. Stores monetize cardboard by selling compacted bales to recycling firms, offsetting disposal costs and even earning rebates. Individuals can also earn by collecting and baling cardboard, though considerations of volume, bale specifications, and local regulations are critical.

(more…) -

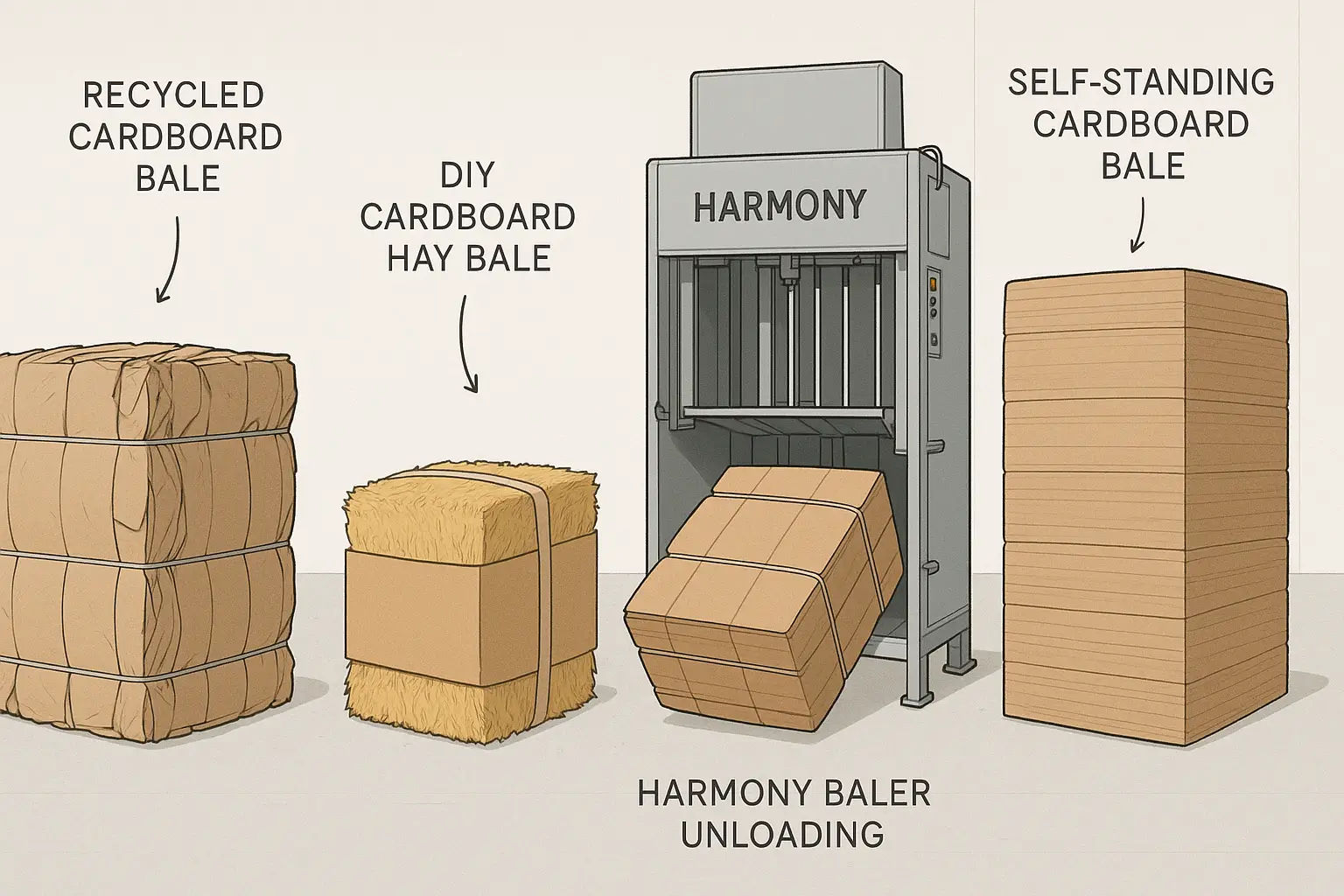

Efficient and Safe Methods for Unloading a Cardboard Baler

Unloading—or emptying—a cardboard baler is a crucial aspect of maintaining smooth operations in any facility that recycles or processes cardboard waste. Proper unloading ensures continued productivity, prevents equipment damage, and safeguards operator safety. This comprehensive guide explores the types of balers, essential safety precautions, step-by-step unloading procedures, troubleshooting tips, and best practices to optimize your baler unloading process.

(more…) -

Comprehensive Guide to Cardboard Balers

Key Takeaway: Proper operation and maintenance of a cardboard baler maximizes compaction efficiency, minimizes downtime, and enhances workplace safety. Understanding the machine’s mechanics, following safety protocols, and adhering to recommended procedures for loading, compacting, and emptying are essential for effective use.

(more…) -

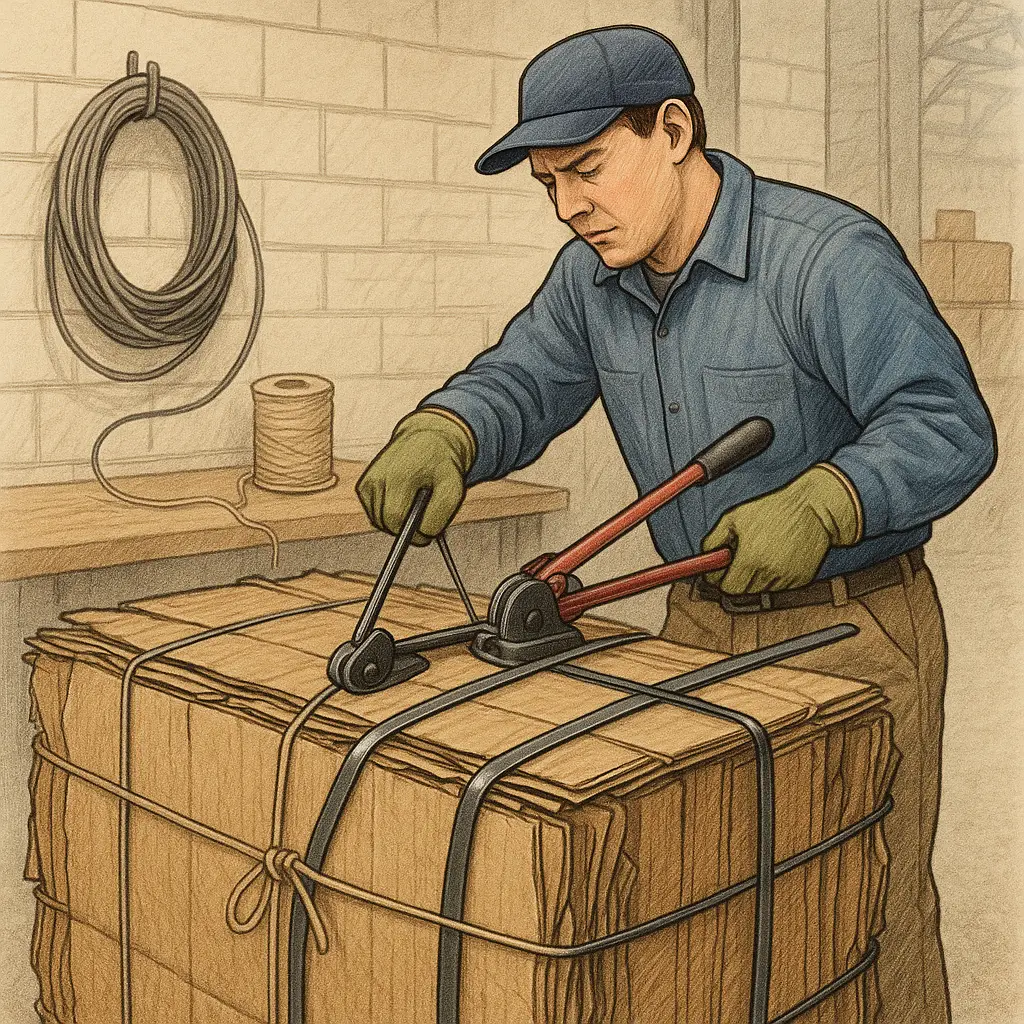

How to Tie a Cardboard Bale

Main Takeaway: Securing a cardboard bale correctly is essential for safe handling, storage, and transportation. Whether using baling wire, polypropylene twine, or steel strapping, following structured preparation, tying, and finishing steps will ensure the bale remains intact and manageable.

(more…) -

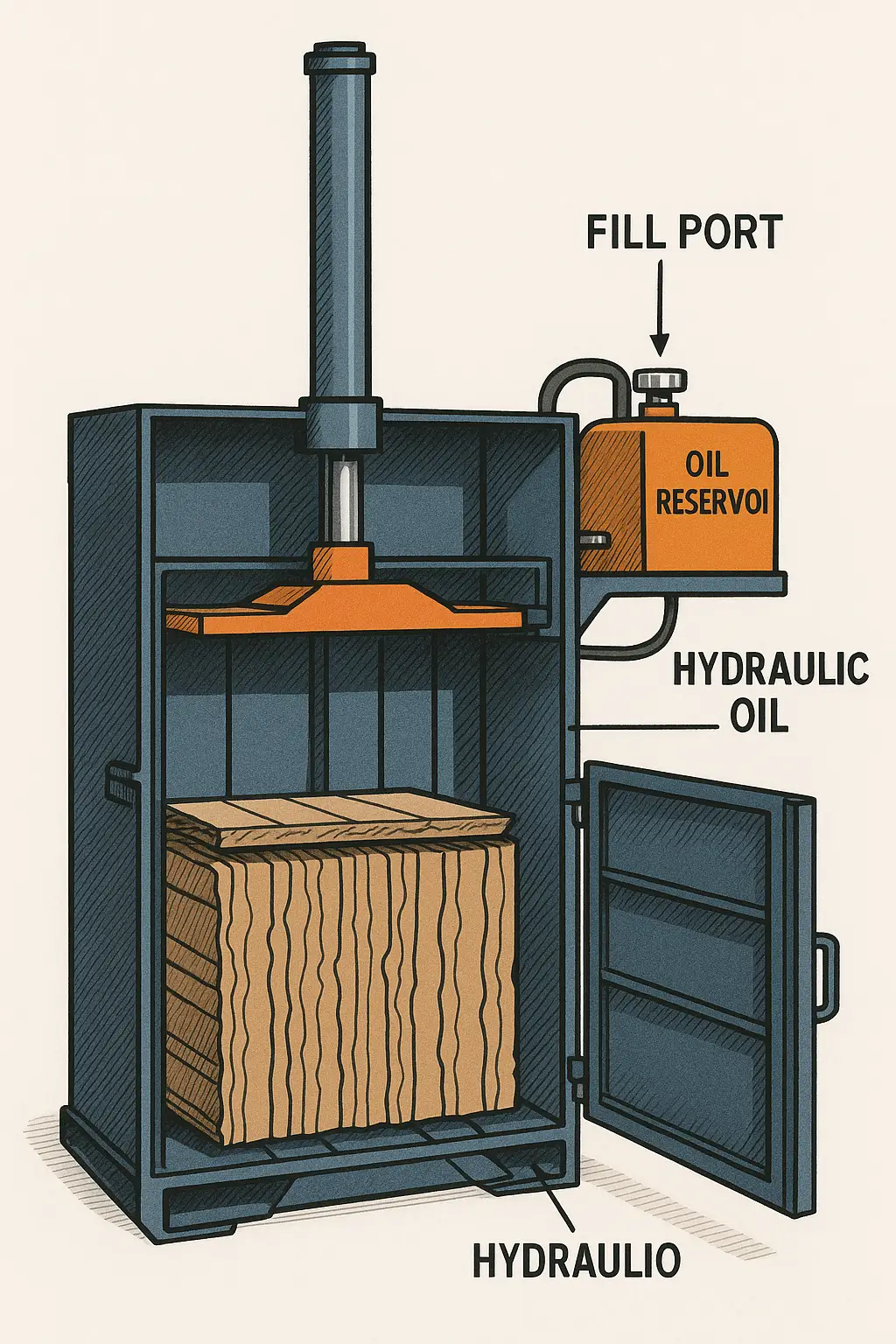

Guide to Resetting, Operating, and Repairing a Cardboard Baler

Key Takeaway: Properly resetting, operating, and maintaining a cardboard baler requires a clear understanding of its hydraulic and electrical systems, adherence to safety protocols, and systematic troubleshooting. Regular inspections and preventive maintenance will drastically reduce downtime and extend equipment life.

(more…) -

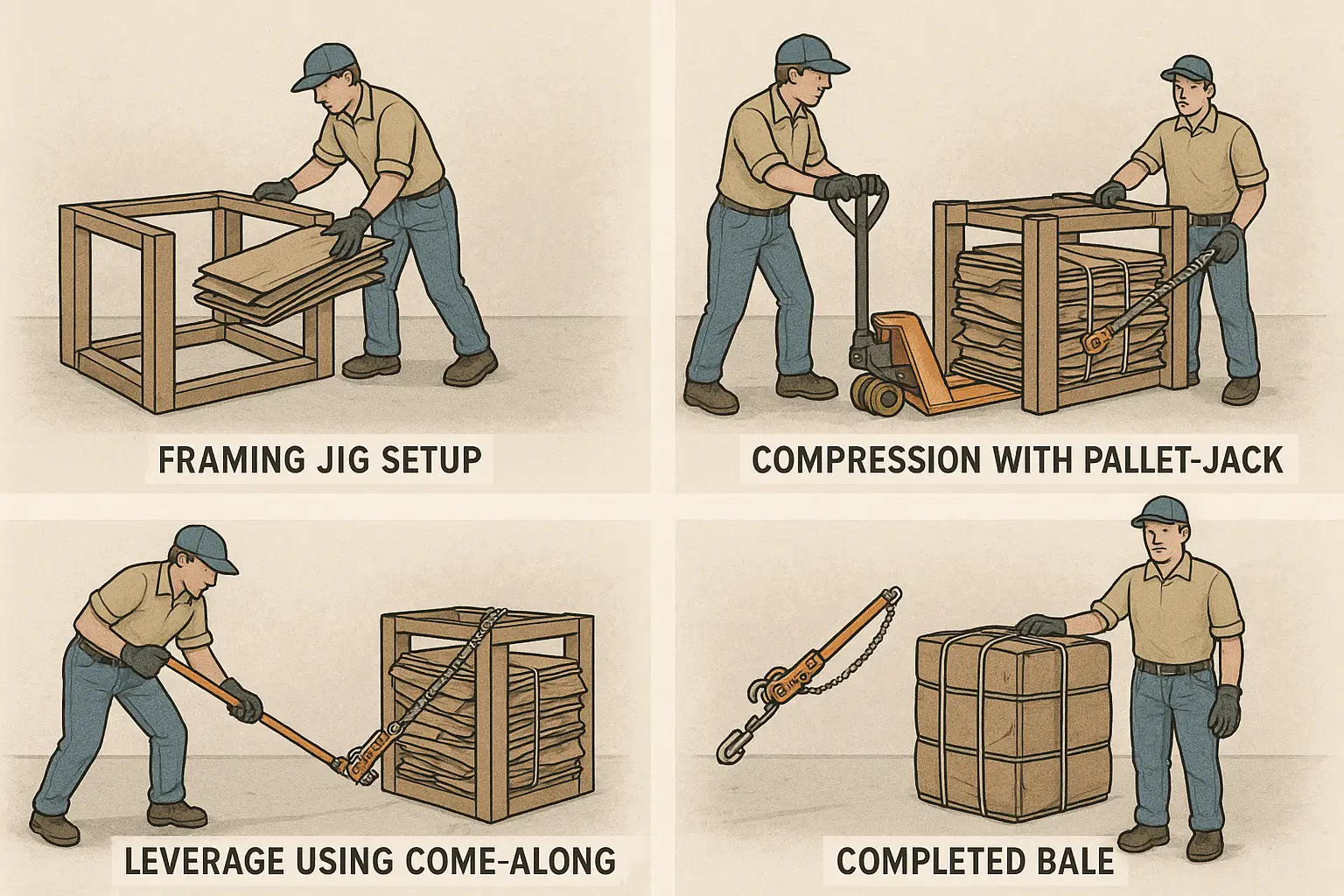

Guide to Baling Cardboard for Recycling and Storage

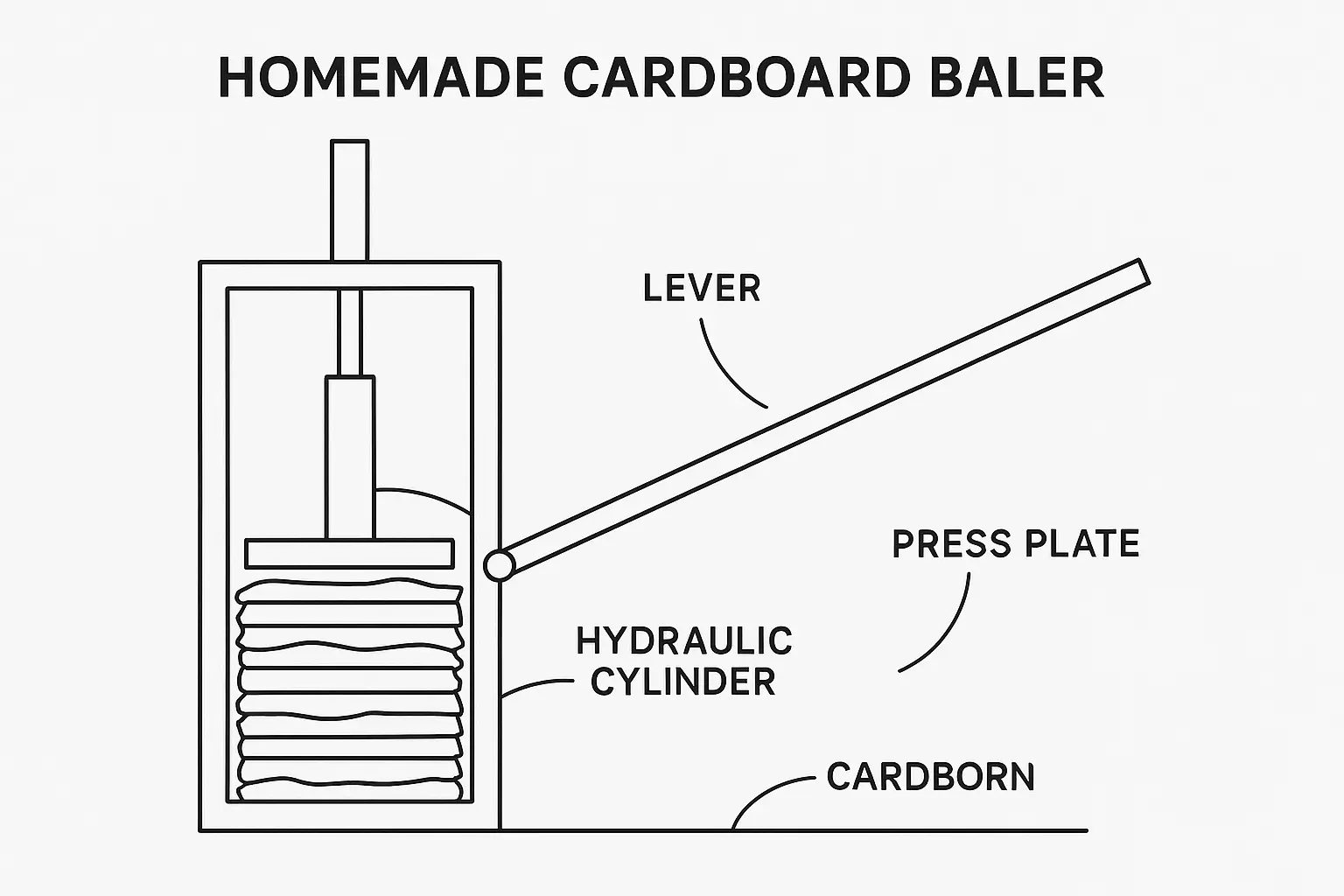

Efficiently baling cardboard is essential for any business, warehouse, retail outlet, or large-scale recycling operation. Well-formed bales save space, streamline handling, and improve the economics of recycling by reducing transportation costs. This guide covers everything from DIY methods to semi-automated processes, addressing how to bale cardboard without a baler, how to construct corrugated cardboard bales, how to tie and palletize bales, and tips specific to common settings such as retail stores and distribution centers.

(more…) -

Guide to Efficient Cardboard Baling

Key Takeaway: Proper operation and maintenance of a cardboard baler optimize throughput, safety, and equipment longevity. Monitor fill indicators, follow safe removal and changeover procedures, and adopt efficient loading techniques to maintain production flow. Most balers complete a full bale cycle in 2–5 minutes, depending on model and operator efficiency.

(more…) -

Cardboard Baler Hydraulic Oil: Capacity, Type, and Consumption

Key Takeaways: A standard vertical cardboard baler holds between 18 and 30 gallons of hydraulic oil in its reservoir. Most manufacturers recommend anti-wear, all-weather hydraulic oils in viscosity grades ISO 32, ISO 46, or AW 68, chosen based on ambient temperature and duty cycle. Routine oil changes are typically performed every 1,000–2,000 operating hours (or annually), and unaddressed leaks can cause annual oil consumption to exceed 100 gallons per machine.

(more…) -

Cardboard Bale Value: Analysis and Market Overview

Key Takeaway: A standard cardboard bale, weighing between 800 and 1,000 lbs (0.4–0.5 ton), is currently worth approximately $20 to $95 per bale in the U.S. market—equating to $40–$190 per ton—with prices influenced by regional demand, bale quality, market trends, and transportation costs. Understanding these factors is essential for maximizing revenue from cardboard recycling and optimizing waste-management strategies.

(more…) -

Market Value of Baled Cardboard Today

Main Takeaway: Baled cardboard is a modestly valued commodity whose price fluctuates with fiber markets, supply–demand dynamics, bale quality, and regional factors. As of August 2025, U.S. scrap‐yard prices average about $66.67 per ton, yielding roughly $22 per 660 lb bale. Prices can range from $40 to $95 per ton (≈$13–$31 per bale), while U.K. rates span £50–£150 per ton. Understanding these ranges, bale weights, quality grades, and timing can help sellers and buyers optimize revenue and costs.

(more…) -

Cardboard Bale Costs: An In-Depth Analysis

Key Takeaway: The cost of a bale of cardboard varies widely—from approximately $20 to $300 per metric ton (equating to $6–$90 per typical 300–900 kg bale)—depending on geography, bale weight and dimensions, material quality, market demand, and logistical factors. Understanding these variables enables businesses and recyclers to optimize revenue, reduce waste-management expenses, and capitalize on recycling markets.

(more…) -

Comprehensive Analysis of Cardboard Bale Weight and Size

The weight and size of a bale of cardboard vary widely depending on the baling equipment, bale type, compaction ratio, moisture content, and intended use. Understanding these variables is essential for logistics, recycling efficiency, space planning, and revenue optimization. Below is an in-depth exploration, covering:

(more…) -

Maximizing Revenue from Cardboard Bales

Key Takeaway In today’s fluctuating recycling markets, sellers can expect to receive anywhere from $40 to $120 per ton of baled corrugated cardboard under typical conditions, with occasional extremes ranging from $20 up to $210 per ton based on regional demand, bale quality, and prevailing commodity prices. Achieving top-dollar requires producing mill‐size bales, maintaining high material quality, and timing sales to market peaks.

(more…) -

Maximizing Cardboard Bale Loading on Semi-Trailers and Flatbeds

Key Takeaway: A standard 53 ft × 8.5 ft semi-trailer can hold between 60 and 117 common cardboard bales, depending on bale dimensions and stacking height. Flatbed trailers of the same footprint accommodate similar bale counts but require secure strapping and weather protection.

(more…) -

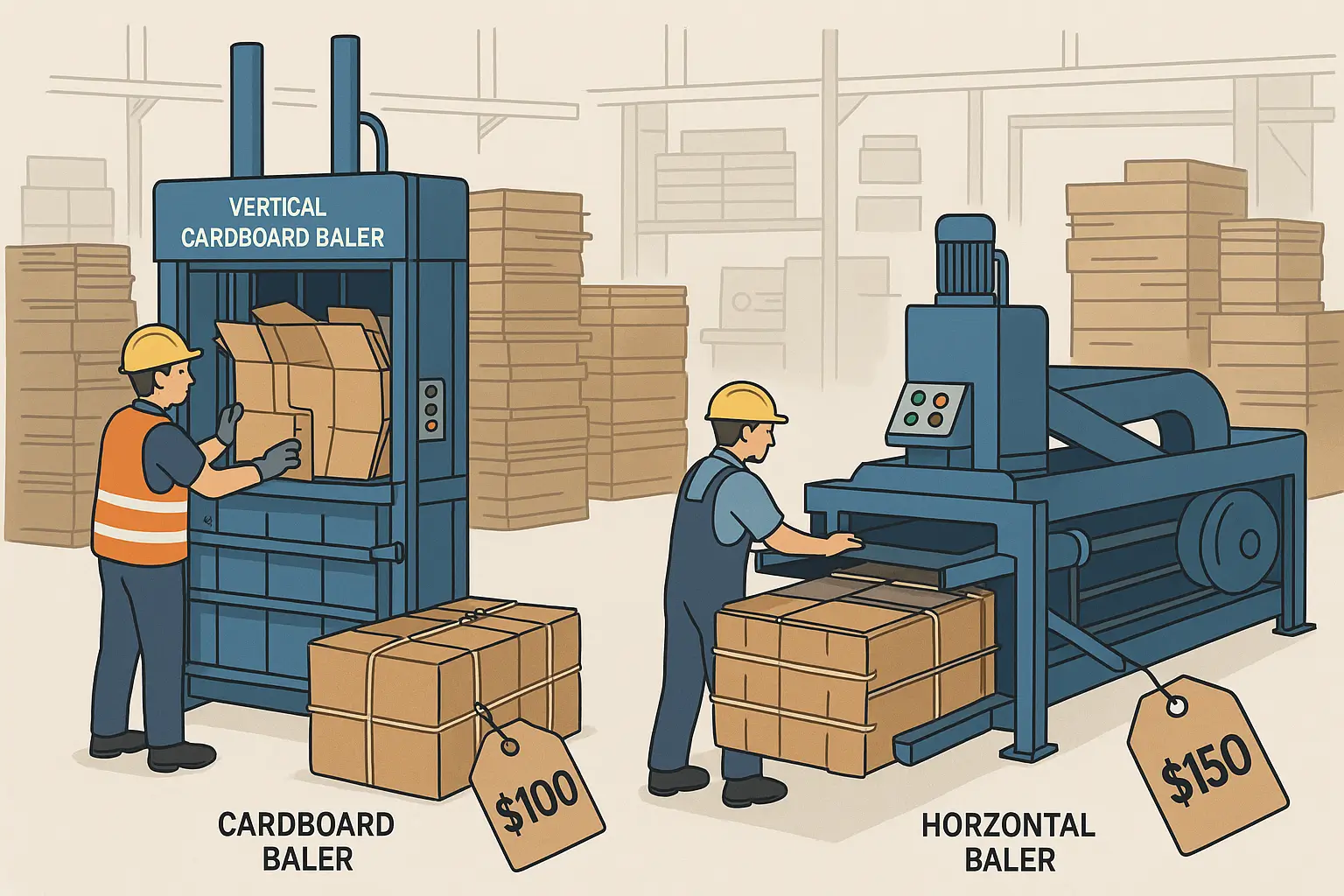

Cardboard Baler Cost Analysis and Pricing Guide

Main Takeaway: Investing in a cardboard baler typically requires an upfront expense ranging from approximately $3,000 for basic vertical models to over $100,000 for fully automated, high-capacity horizontal balers. The optimal choice hinges on waste volume, available space, budget, and desired level of automation—balancing initial purchase price against long-term operational savings.

(more…) -

Comprehensive Guide to Building a Homemade Cardboard Baler

Key Takeaway: Constructing a DIY cardboard baler is an achievable project that can dramatically reduce waste volume, streamline recycling, and save costs. By carefully selecting materials, tools, and a suitable design—whether manual, hydraulic, or mechanical—you can build a safe, efficient baler tailored to your needs.

(more…) -

How to Move a Cardboard Baler

Moving a cardboard baler is a complex task that demands meticulous planning, careful preparation, proper equipment, and attention to safety. Cardboard balers are heavy, bulky machines used in recycling facilities, warehouses, retail stores, and manufacturing plants to compress and bind cardboard waste into manageable bales. Whether you’re relocating a baler within the same facility, installing it at a new site, or reconfiguring your production line, this guide will walk you through each step required to move a cardboard baler safely and efficiently.

(more…)