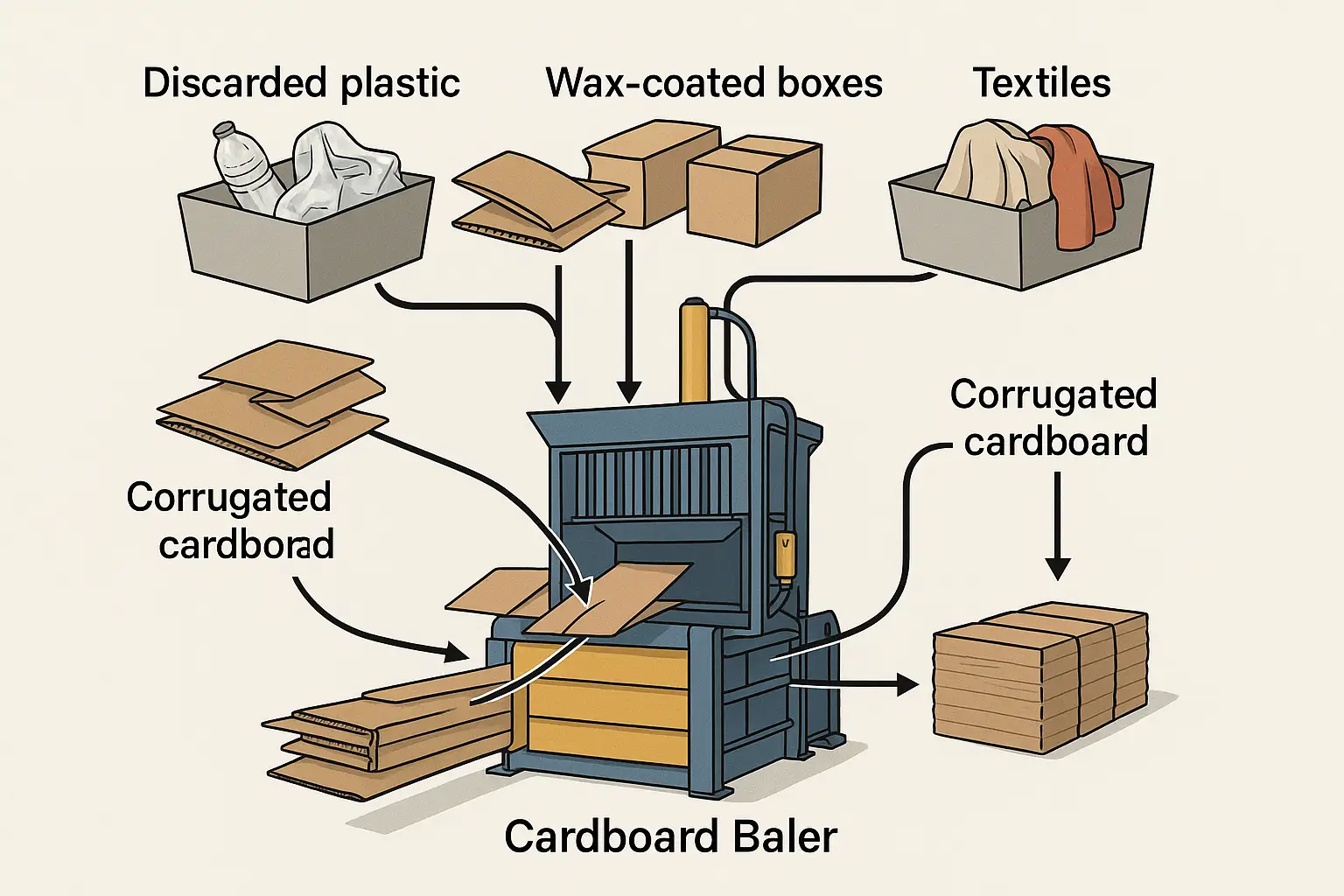

Efficient cardboard baling lies at the heart of sustainable waste management and recycling operations. A properly configured baler can process large volumes of corrugated cardboard into dense, transportable bales, reducing hauling costs and material footprint. However, maximizing the value and purity of cardboard bales requires careful attention to feedstock specifications, permissible materials, and contamination controls. The following sections examine:

- Recommended types of cardboard suited for mechanical balers

- Feasibility and considerations of using cardboard balers for textiles

- Handling wax-coated boxes in cardboard baling

- Impacts and mitigation of plastic contamination in cardboard bales

1. Ideal Cardboard Types for Baling

1.1 Corrugated Cardboard (Fluted Board)

Corrugated cardboard—also known as fluted board—is the industry standard for baling:

- Structure: Comprised of one or two outer linerboards sandwiching a fluted medium.

- Strength: Flutes (A, B, C, E, F sizes) confer rigidity and stacking capacity.

- Recyclability: High cellulose content and fiber length make it ideal for pulping.

Key Considerations:

- Moisture Content: Optimal at 8–12% to prevent fiber degradation or mold growth during storage.

- Size Prep: Flattened and stripped of non-cardboard attachments (metal staples, strapping, plastic windows) to ensure smooth feeding and compaction.

- Contamination Threshold: Non-paper contaminants must remain below 1–3% by weight to meet mill specifications.

1.2 Single-Face and Double-Face Cardboard

- Single-Face: Fluted medium bonded to a single liner; less sturdy and often sourced from packaging liners or protective pads.

- Double-Face: Fluted medium with liners on both sides; behaves identically to corrugated, albeit sometimes thinner.

These lower-grade boards can be baled alongside standard corrugated cardboard, provided contamination is minimal. They yield slightly lower recoverable fiber but remain acceptable at most recycling mills.

1.3 Folding Carton and Paperboard

Folding cartons (e.g., cereal boxes, shoeboxes) and chipboard are technically cardboard but differ in fiber content:

- Fiber Quality: Shorter fibers yield weaker pulp; mill preferences vary.

- Mixed Baling: Up to 5–10% folding carton content is permissible in corrugated bales, but higher proportions may downgrade bale grade (e.g., from “OCC” to “PS” grade).

Recommendation: Separate high-value corrugated from folding carton when feasible; bale them separately if volumes warrant.

2. Using a Cardboard Baler for Clothing

2.1 Mechanical Compatibility

Cardboard balers are designed for flat, rigid materials. While they can compress a variety of bulky items, clothing presents unique challenges:

- Compressibility: Soft goods collapse under pressure, creating dense but irregular bales that may jam feed chambers.

- Feeding Mechanism: Clothing can entangle on shear blades or push rollers, causing mechanical downtime and maintenance.

2.2 Safety and Operational Considerations

- Fire Hazard: Textiles, especially synthetics, can generate static electricity and sparks during compaction, elevating fire risk.

- Odor and Hygiene: Used clothing may harbor moisture, bacteria, or pests; baler interiors require thorough cleaning post-compaction.

- Contamination Risk: Textile fibers can embed in hydraulic seals and electronic sensors, increasing wear.

2.3 Alternative Equipment

- Textile Balers: Specifically engineered with wider loading chambers, adjustable compression cycles, and anti-wrap mechanisms.

- Garment Bailers: Often utilize slower piston speeds and incorporate knife guards to prevent entanglement.

Conclusion: While possible in an emergency, using a cardboard baler for clothing is not recommended. Dedicated textile balers ensure higher throughput, minimal downtime, and compliance with waste-processing regulations.

3. Baling Wax-Coated (Waxed) Boxes

3.1 Nature of Wax Coatings

Waxed boxes are treated with paraffin or polyethylene to resist moisture (e.g., produce boxes, freezer boxes):

- Hydrophobic Barrier: Prevents water absorption but also inhibits pulping.

- Wax Type: Food-grade paraffin wax versus polyethylene coatings differ in melting point and removability.

3.2 Impacts on Recycling

- Pulp Contamination: Wax does not dissolve in water. During pulping, wax melts or floats, forming a layer of hydrophobic debris (“stickies”) that coat fibers and machinery.

- Mill Acceptability: Most packaging mills set rigid limits (often ≤1% wax content by weight). Exceeding this leads to bale rejection or down-grading.

3.3 Pre-Processing Techniques

- Wax Remediation: Some facilities use alkali washes or hot water floatation to detach wax prior to pulping. This requires specialized tanks and chemicals, adding cost.

- Physical Removal: Scraping or abrasion can remove surface wax but is labor-intensive and impractical at scale.

3.4 Baler Jurisdictions

- Regional Policies: Many municipal recycling programs explicitly prohibit waxed cardboard in curbside OCC (Old Corrugated Containers) bales.

- Industrial Sorting: Material recovery facilities (MRFs) may manually or optically sort wax-coated board into residue streams.

Best Practice: Exclude waxed boxes from standard cardboard bales. Instead, route them to specialized organics or mixed paper streams equipped to handle coatings.

4. Consequences of Plastic Contamination in Cardboard Bales

4.1 Sources of Plastic Contaminants

- Stretch Wrap and Strapping: Often left attached to pallets or bundles.

- Laminated or Coated Paperboard: Retail displays coated in plastic lamination.

- Plastic Windows: On mailing envelopes or some folding cartons.

4.2 Effects on Bale Quality

- Downgrading: Plastic residue automatically lowers bale grade (from Grade 11 OCC to Grade 56 “PS2” or lower), reducing its market value by 10–30%.

- Mill Processing Issues:

- Stickies: Molten plastic agglomerates can adhere to wires, screens, and rollers in pulpers and cleaners.

- Equipment Damage: Plastic can tangle in centrifugal cleaners, causing blockages and hydraulic failures.

- Increased Rejects: Excess plastic fragments end up in reject streams, raising disposal costs.

4.3 Environmental and Safety Concerns

- Microplastics Release: Pulping does not break plastics into harmless pieces; instead, it generates microplastics that may escape to wastewater.

- Combustion Off-Gassing: If bales are incinerated for energy recovery, mixed plastics emit toxic fumes (dioxins, VOCs).

4.4 Mitigation Strategies

- Rigorous Pre-Sort: Manual or optical sorting at the MRF to remove visible plastics, stretch wrap, and laminates.

- Wash Systems: Advanced pulping lines incorporate friction washers. However, complete removal of fine plastic particulates is rare.

- Education and Enforcement: Training staff and suppliers on bale specifications; issuing swap-out penalties for off-spec loads.

- Automated Detection: Near-infrared (NIR) sensors can identify plastic items on conveyor belts, diverting them before baling.

5. Integrated Best Practices for High-Value Cardboard Bales

5.1 Material Preparation

- Flattening and Stripping: Unfold boxes and cut or tear off all non-paper components (staples, labels, tape residue).

- Moisture Control: Store cardboard under cover; avoid direct contact with rain or sprinkler systems.

5.2 Segregation Protocols

- Dedicated Streams: Establish separate bins for corrugated OCC, waxed cardboard, paperboard, and textiles.

- Labeling: Clearly mark collection areas to reduce cross-contamination.

5.3 Equipment Maintenance

- Routine Inspections: Check hydraulic seals, shear blades, and feed rollers for foreign debris accumulation.

- Cleaning Schedule: Implement weekly wash-downs of internal chambers to remove tape adhesive, wax, and dust.

5.4 Quality Assurance

- Bale Sampling: Periodically shred sample bales and quantify non-paper contaminants; aim for <1% plastics and <0.5% wax by weight.

- Supplier Feedback: Issue reports to upstream generators detailing contamination rates; incentivize cleaner loads.

5.5 Regulatory Compliance

- Recycling Standards: Adhere to guidelines such as ISRI Paper & Paperboard grades or CAG Auctions specifications.

- Environmental Permits: Ensure that any wash water or reject streams comply with local discharge and waste disposal regulations.

Conclusion

Maximizing the value and recyclability of cardboard bales depends on selecting the appropriate feedstock, excluding non-paper materials, and proactively managing potential contaminants. Standard corrugated cardboard and double-face board form the ideal bale composition, while folding cartons may be included in small proportions. Using cardboard balers for textiles is ill-advised due to mechanical and safety concerns, and wax-coated boxes should be segregated to specialized streams to prevent pulping disruptions. Finally, even minor plastic contamination can significantly downgrade bale quality, elevate processing costs, and generate environmental hazards. By implementing rigorous sorting, material preparation, and quality control protocols, recycling operations can produce high-grade, mill-ready bales that command premium pricing and support a circular economy.

Leave a Reply