Palletizing fragile items is key to making sure they arrive safely. Seventy-four percent of U.S. consumers see packaging as key in buying choices. Proper palletizing can cut product damage by up to 90%. So, businesses that ship fragile items must master this skill. This guide shows how to safely palletize fragile items. Choose the right materials and use safe methods for your shipments.

Understanding Fragility in Shipping

What Makes Items Fragile

Fragile items can break easily when pressure or shock is applied, instead of bending. This category includes glassware, ceramics, electronics, art prints, antiques, and lightweight jewelry. These items are particularly susceptible to impact, vibrations, and improper handling during transportation.

The Challenges of Shipping Fragile Goods

Shipping fragile items presents several key challenges:

- High Damage Risk: Small falls or sudden moves can crack or break fragile items if they aren’t secured well.

- Packaging Errors: Inadequate or low-quality packaging materials often fail to provide sufficient protection.

- External Factors: Fragile shipments can be affected by unpredictable transportation. Rough handling during loading and unloading, poor roads, and bad weather matter too.

- Mislabeling Issues: Without “fragile” labels, items may get treated as regular cargo. This raises the chance of mishandling.

Essential Materials and Equipment

Selecting the Right Pallet

To safely palletize, start with the right pallet material and design:

- Hardwood Pallets: Strong and durable, ideal for heavy and high-value fragile items. Their strong structure supports heavy weights and resists damage. This makes them great for frequent use.

- Softwood Pallets: Lighter than hardwood but still provide good support for medium-weight items.

- Plastic Pallets: They are strong, light, and resist moisture. This makes them great for fragile items needing protection from the environment.

- Size Considerations: Choose a pallet that fits all items. It should be at least 48” long and 40” wide, so nothing hangs over the edges.

Essential Packaging Materials

A successful palletizing operation requires these key materials:

- A sturdy pallet without loose boards

- Stretch wrap (shrink wrap)

- Strapping materials (rope, twine, or ratchet straps)

- Protective materials (foam, bubble wrap, cardboard)

- Edge protectors

- Clear labeling supplies

Step-by-Step Palletizing Process for Fragile Items

1. Preparation and Individual Packaging

Before placing items on the pallet, ensure each fragile piece is properly packaged:

- Use good cushioning materials for packing. Foam inserts, bubble wrap, and egg-crate foam work well.

- Choose strong corrugated cardboard boxes that are 10-25% bigger than your items. This extra space lets you add enough padding.

- For extremely fragile items, consider double-boxing with cushioning between both boxes.

2. Strategic Item Placement

The way you arrange items on the pallet significantly impacts their safety:

- Place packaged fragile items in the center of the pallet. This helps protect them from outside impacts.

- Position items to evenly distribute weight across the pallet surface.

- Stack items so they remain level, square, and close to one another on the pallet.

- Place larger and heavier items on the bottom, with smaller and lighter items toward the top.

- Keep everything on the pallet. If items hang over the edge, the pallet might absorb any impact instead of the items.

3. Creating Stable Layers

Building stable layers is critical for preventing damage:

- For multi-layered stacks, place cardboard sheets or layer pads between layers. This helps distribute weight and adds stability.

- Maintain consistent layer patterns to ensure structural integrity throughout the pallet load.

- The total height of stacked items should not exceed 6 feet to maintain stability.

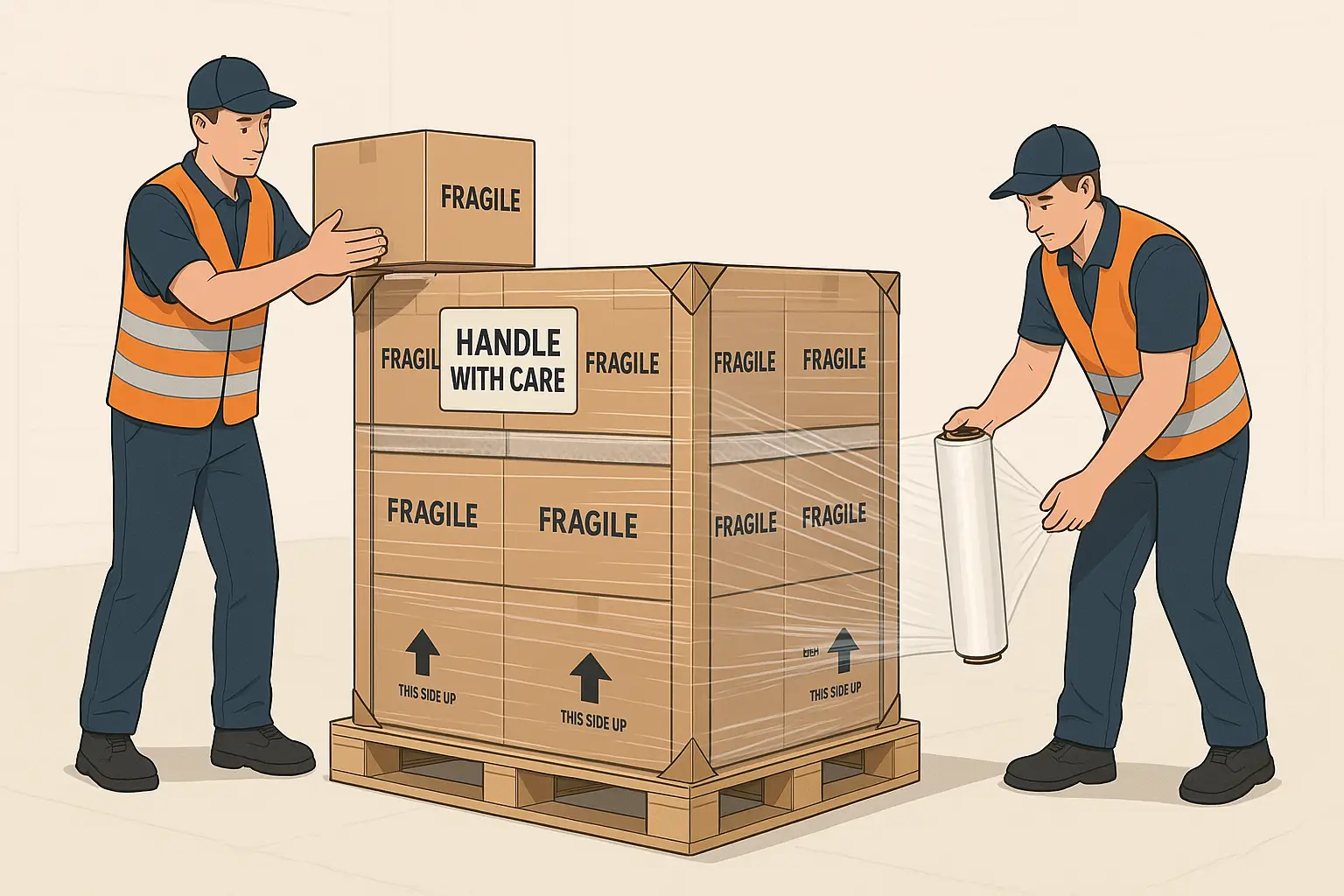

4. Securing the Load

Proper securing techniques prevent shifting during transit:

- Take your stretch wrap and thread about 8 inches of the end through one corner of the pallet to anchor it.

- Wrap multiple times around the base to create a strong foundation.

- Continue wrapping upward in an overlapping pattern, covering all sides of the load.

- Add cardboard edge protectors to corners before wrapping. This helps prevent damage from the stretch film tension.

- Use strapping or banding for additional security, especially for heavier items.

5. Final Packaging Considerations

Complete the palletizing process with these important final steps:

- Apply “Fragile” labels clearly on multiple sides of the pallet.

- Add specific handling instructions such as “This Side Up” or “Handle with Care”.

- Conduct a final inspection to ensure nothing is loose and the load is stable.

- Test your packaging by gently pushing on the load. Check for any movement.

Best Practices for Specific Types of Fragile Items

Electronics and Appliances

Electronics and appliances require special consideration:

- Use anti-static packaging materials for electronic components to prevent damage from static electricity.

- Ensure all detachable parts are secured or removed and packaged separately.

Glassware and Ceramics

These highly breakable items need extra attention:

- Wrap each piece individually with bubble wrap or specialized foam sleeves.

- Create cells or compartments within boxes to prevent items from touching each other.

Artwork and Antiques

For valuable and irreplaceable items:

- Consider custom crating rather than standard palletizing for extremely valuable pieces.

- Use corner protectors and rigid backing materials to prevent bending or warping.

- Implement climate-controlled packaging for items sensitive to temperature or humidity.

Overcoming Common Palletizing Challenges

Preventing Movement During Transit

Movement is the enemy of fragile items during shipping:

- Fill empty spaces with cushioning materials like bubble wrap or packing peanuts.

- Ensure stretch wrap is applied tightly and covers the entire load, including the top.

- Consider using non-slip materials between layers to increase stability.

Balancing Protection and Cost-Efficiency

Efficient palletizing considers both protection and cost:

- Avoid overusing packaging materials, which can increase shipping costs and environmental impact.

- Focus on strategic placement and proper securing techniques rather than excessive packaging.

- Consider implementing automated packaging systems for consistent results, especially for high-volume shipping.

Addressing Environmental Factors

Protect against environmental challenges during shipping:

- Use waterproof bags or shrink wrap to protect against moisture damage.

- Consider temperature-resistant packaging for items sensitive to heat or cold.

- Implement humidity controls for items that can be damaged by moisture.

Useful Summarization Table

| Step/Aspect | Description & Best Practices | Key Materials/Tools | Common Mistakes to Avoid |

|---|---|---|---|

| 1. Item Assessment | Identify fragility, weight, size, and packaging needs for each item | Packing list, measuring tape | Ignoring item-specific needs |

| 2. Select Packaging | Use sturdy, new boxes sized for cushioning; wrap items individually | Corrugated boxes, bubble wrap, foam | Reusing weak boxes, thin padding |

| 3. Cushioning | Place foam, bubble wrap, or peanuts around each item and between items/layers | Bubble wrap, foam, packing peanuts | Insufficient cushioning |

| 4. Pallet Choice | Use undamaged, appropriately sized pallets (wood or plastic) | Wood/plastic pallet | Damaged or undersized pallets |

| 5. Stacking Pattern | Stack heaviest items at bottom, lighter/fragile at top; use interlocking or column pattern | Layer pads, cardboard sheets | Overloading, uneven stacking |

| 6. Layer Separation | Separate layers with cardboard or wood for added stability | Cardboard/wood layer pads | Skipping layer separation |

| 7. Void Filling | Fill gaps to prevent movement | Packing peanuts, airbags | Leaving empty spaces |

| 8. Edge Protection | Use edge/corner protectors to prevent crushing and strap damage | Edge/corner protectors | No edge protection |

| 9. Securing Load | Wrap entire pallet tightly with stretch or shrink wrap; use straps if needed | Stretch/shrink wrap, straps | Loose wrapping, weak strapping |

| 10. Labeling | Clearly label as “Fragile,” “Handle with Care,” and provide orientation instructions | Fragile labels, handling stickers | No or unclear labeling |

| 11. Inspection | Final check for stability, security, and labeling before shipping | Visual inspection | Skipping final inspection |

Leave a Reply