Accurately measuring your box dimensions is crucial for determining shipping costs, ensuring proper handling, and preventing delays or additional fees. This guide covers every aspect of measuring a box for shipping, from understanding why it matters to step-by-step instructions, tips for odd-shaped packages, and practical examples.

Why Proper Box Measurements Matter

1. Cost Calculation Most carriers use dimensional weight (DIM) pricing, which factors in both the package’s actual weight and its size. If a box is large but light, the carrier may charge based on the space it occupies rather than its scale weight.

- Incorrect measurements can lead to underestimated shipping costs and surprise surcharges.

- Precise measurements help you choose the most economical service option.

2. Packaging Efficiency

- Right-sized boxes minimize shipping fees and material costs.

- Prevent wasted space inside the box, reducing the risk of damage due to shifting contents.

3. Compliance and Avoiding Delays Carriers enforce size limits. Oversized parcels may incur over-dimensional fees or even be refused. Accurate measurements guarantee that your shipment meets carrier guidelines and avoids delays.

Key Terms and Concepts

Before diving into the how-to, let’s clarify some essential terms:

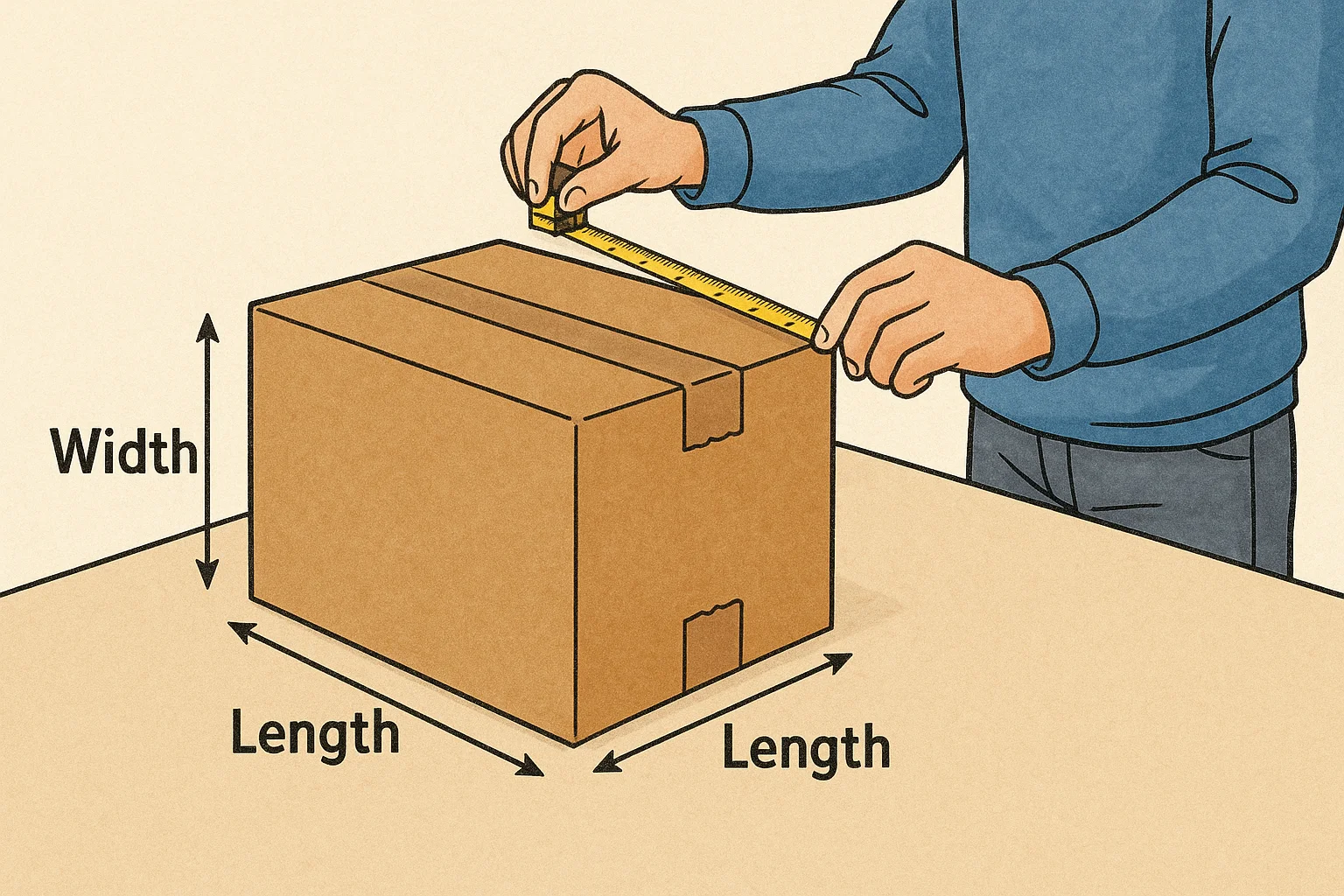

- Length (L): The longest side of the box.

- Width (W): The side perpendicular to the length; the shorter side of the box opening.

- Height (H): The vertical distance from the base to the top of the box when it’s sitting in its standard orientation.

Dimensional Weight DIM weight is calculated as (L × W × H) ÷ a divisor specified by the carrier (for example, 139 for UPS and FedEx domestic shipments). Carriers bill whichever is greater: actual weight or DIM weight.

Step-by-Step Measurement Guide

Follow these steps every time to ensure consistency and accuracy:

1. Prepare Your Tools

- Tape Measure or Ruler: A flexible tape measure provides precise readings even on irregular edges.

- Flat Surface: Place the box on a stable, level floor or table to avoid measurement errors.

- Permanent Marker: To mark measurement start and end points if needed.

2. Orient the Box Correctly

Set the box on its flattest side with the opening flaps closed and sealed, oriented as you would stack it. This position defines the proper Length, Width, and Height.

3. Measure Length (L)

- Identify the longest side of the box’s face.

- Place the tape measure at one corner of this face and extend it to the opposite corner.

- Record the measurement to the nearest 1/8 inch (or millimeter).

4. Measure Width (W)

- On the same face, measure the shorter side, perpendicular to the length.

- Place the tape at one corner and extend it to the opposite corner.

- Record accurately, matching the unit used for the length.

5. Measure Height (H)

- Measure from the base (where the box sits) to the highest point on the top, including any sealed flap thickness.

- Ensure the scale stays vertical for a true height reading.

6. Verify Measurements

- Double-check each dimension once more.

- If the box has bulges or uneven surfaces, measure at the widest or tallest points.

Recording and Using Dimensions

Once you have L, W, and H:

- Round Up to the Nearest 1/8 Inch: Carriers round up fractional inches, so measure as precisely as possible and then round up.

- Calculate DIM Weight:

$$ \text{DIM Weight (lbs)} = \frac{L \times W \times H}{\text{DIM Divisor}} $$

For example, a box measuring 20″ × 15″ × 10″ with a divisor of 139 yields:

$$ \frac{20 \times 15 \times 10}{139} = \frac{3000}{139} \approx 21.6 \text{ lbs} $$

- Compare to Actual Weight: Use a scale to measure the packed box. The greater of the two weights determines the billable weight.

Tips for Special Cases

Irregular or Non-Rectangular Packages

- Cylinders/Tubes: Measure length as the tube’s length and width as twice the radius (i.e., diameter). Height equals the same width measurement if the tube is round.

- Soft Packages (Envelopes, Padded Bags): Measure the overall envelope when fully expanded and flattened.

- Odd Shapes: Place the item in the smallest rectangular box that encloses it. Measure that box.

Nested or Multi-Box Shipments

When shipping multiple boxes together, each box is measured and weighed separately. Prices are based on individual box weights and dimensions, then added together for the total shipment cost.

International Shipping Considerations

- Different carriers and countries may have unique divisors or measurement requirements (e.g., metric units).

- Always confirm specific regulations with the carrier or customs documentation.

Common Mistakes and How to Avoid Them

| Mistake | Impact | Prevention |

|---|---|---|

| Measuring at midpoints rather than extremes | Underestimates size, leading to fees | Measure at the box’s fullest dimensions |

| Ignoring flap or bulge thickness | Underreporting height | Include sealed flap thickness in height measurement |

| Inconsistent units (mixing inches/cm) | Invalid DIM calculations | Stick to one unit system and convert if necessary |

| Forgetting to round up | Still underestimates billable size | Always round up fractional inches to next whole increment |

| Not resealing before measuring | Gaps alter true dimensions | Seal flaps completely before measuring |

Practical Examples

Example 1: Standard Cardboard Box

- Measured: 18.25″ (L) × 12.5″ (W) × 9.75″ (H)

- Rounded: 18.25″ → 19″, 12.5″ → 13″, 9.75″ → 10″

- DIM Weight: (19 × 13 × 10) ÷ 139 ≈ 17.8 lbs → 18 lbs

- Actual Weight (scale): 15 lbs

- Billable Weight: 18 lbs

Example 2: Cylindrical Tube

- Measured: Length 36″; diameter 4″

- L = 36″; W = H = 4″

- DIM Weight: (36 × 4 × 4) ÷ 139 ≈ 4.1 lbs → 5 lbs

- Actual Weight: 3 lbs

- Billable Weight: 5 lbs

Selecting the Right Packaging Material

- Heavy Items: Use double-wall corrugated boxes to maintain shape and integrity.

- Light but Bulky Items: Single-wall boxes suffice, but dimensions drive cost-choose the smallest possible size.

- Fragile Items: Add cushioning (bubble wrap, packing peanuts) but remember to re-weigh and re-measure after padding.

Tools and Technology for Streamlining Measurement

- Automated Dimensioning Systems: Used by industrial shippers and warehouses; lasers and imaging determine box dimensions instantly.

- Mobile Apps: Some carriers offer smartphone apps that estimate dimensional weight by capturing images and using augmented reality.

- Integrated Shipping Software: Automates dimension and weight recording, compares carrier rates, and selects the cheapest option automatically.

Final Recommendations

- Measure Every Time: Never assume two boxes are identical; slight variations can affect pricing.

- Document Precisely: Keep records of actual vs. DIM weight for audit and cost-control.

- Invest in Quality Tools: A durable tape measure, digital scale, or even an automated dimensioner improves accuracy.

- Stay Informed on Carrier Policies: Carriers periodically update divisors and packaging guidelines-review their websites regularly.

By rigorously measuring your boxes and understanding how carriers calculate dimensional weight, you can optimize shipping costs, avoid unexpected fees, and improve overall packaging efficiency. Accurate measurements are a simple yet powerful lever for any business or individual who ships items regularly.

Leave a Reply