Efficiently baling cardboard is essential for any business, warehouse, retail outlet, or large-scale recycling operation. Well-formed bales save space, streamline handling, and improve the economics of recycling by reducing transportation costs. This guide covers everything from DIY methods to semi-automated processes, addressing how to bale cardboard without a baler, how to construct corrugated cardboard bales, how to tie and palletize bales, and tips specific to common settings such as retail stores and distribution centers.

Key Takeaways

- You can bale cardboard effectively without an industrial baler by using manual compression, strapping tools, and simple framing jigs.

- Proper preparation—sorting, flattening, and cleaning—is crucial for bale density, safety, and recycling compliance.

- Securing the bale with strapping or wire must follow consistent patterns to prevent collapse in storage and transit.

- Palletizing bales standardizes handling with forklifts, reduces damage, and integrates easily into existing warehouse workflows.

1. Preparing Cardboard for Baling

1.1 Sorting and Cleaning

Before baling, separate cardboard by type:

- Corrugated cardboard (boxes)

- Paperboard (cereal boxes, thin cartons)

- Mixed fiberboard (tri-wall or heavy-duty sheets)

Remove any contaminants such as plastic wrap, tape, staples, strapping, and food residue. Contaminated material can lower bale quality, incur surcharges from recyclers, or render bales non-recyclable.

1.2 Flattening and Cutting

Flatten boxes completely by cutting or ripping all glued flaps. Use a utility knife to score thick corrugated edges if necessary. Smaller sections (no more than 2 ft×2 ft) stack more uniformly and yield higher-density bales.

2. Baling Cardboard Without a Baler

Industrial balers compress material hydraulically, but small businesses or volunteer organizations can bale by hand with these methods.

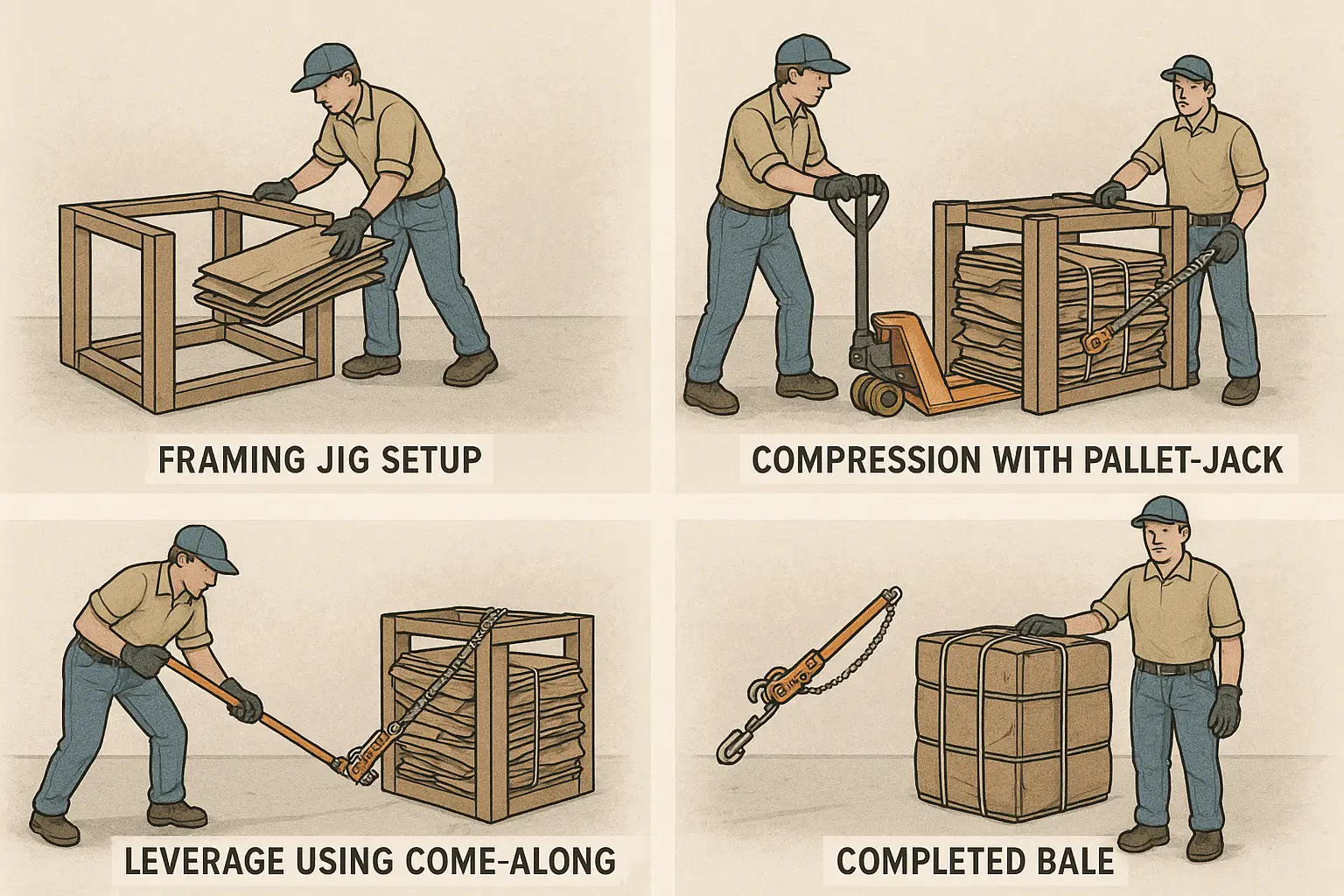

2.1 Framing Jig Method

Construct a simple wooden or metal frame sized to the desired bale dimensions (e.g., 40”×48”×30”).

- Build the Frame:

- Four vertical posts (4 × 4 in timber) at corners.

- Horizontal braces at top and bottom around the perimeter.

- One open side for loading.

- Load and Compress:

- Place flattened cardboard inside the frame in layers, alternating grain directions for stability.

- Use a heavy plate or pallet jack platform atop the stack.

- Apply downward force by stepping, jumping lightly, or using a lever arm (e.g., a steel pipe and fulcrum) to press the plate.

- Strap the Bale:

- With the bale compressed, thread polyester strapping around the width and length, forming a “+” pattern (see Section 3).

- Tension straps with a manual tensioner tool and secure with metal seals or buckles.

- Remove the Frame:

- Once straps are secured, remove side braces to slide the bale out.

2.2 Pallet Jack Compression

If a pallet jack is available but no baler:

- Stack cardboard on a robust pallet to about 36–48 in high.

- Place a flat sheet of plywood or steel plate over the stack.

- Lower the pallet jack saddle onto the plate, driving down to compress.

- While holding pressure, strap the bale as described.

2.3 Manual Leverage Method

For very small volumes (50–100 lb per bale):

- Stack cardboard on the ground within a crisscrossed protective border (e.g., two-by-fours).

- Lay a heavy timber or scaffold plank across the top.

- Hook a chain or rope at each end of the plank and pull downward with a come-along (hand winch) anchored to the floor or another fixed point.

- Strap the bale under tension.

3. Securing and Tying Cardboard Bales

Proper tying is critical to prevent “blooming” (bulging) or collapse during handling. Use high-tensile strapping materials:

- Polyester (PET) strapping: Low stretch, high strength, recyclable

- Polypropylene (PP) strapping: Lower cost, moderate strength, some stretch

- Steel strapping: Highest strength; less common in hand-baling due to safety concerns

3.1 Strapping Pattern

A robust pattern uses six straps:

| Strap Orientation | Number | Placement |

|---|---|---|

| Widthwise | 2 | One near top, one near bottom face |

| Lengthwise | 2 | One near each long side center |

| Diagonal | 2 | Crossing corners from top to bottom |

- Position Straps: Wrap around the bale and feed through the tensioner.

- Tension Straps: Use a hand tensioner to tighten each strap sequentially, maintaining pressure until all straps are in place.

- Seal Straps: Crimp metal seals or fasten buckles; trim strap tails.

3.2 Wire Tying (Alternate Method)

In settings with wire-type balers or for added security:

- Use 12 ga or thicker annealed steel wire.

- Wrap wire similar to strapping, twisting ends together with pliers.

- Excess wire ends must be tucked to avoid injuries.

4. Constructing Corrugated Cardboard Bales

4.1 Optimal Bale Dimensions and Weight

Recyclers typically prefer standardized bale sizes:

- Small bales: 30” × 40” × 36”; 300–350 lb

- Medium bales: 40” × 48” × 48”; 500–600 lb

- Large bales: 48” × 60” × 60” (full pallet); 700–900 lb

Aim for 10–15 lb / cu ft density. Achieve this through thorough flattening and robust compression methods.

4.2 Layering Technique

Alternate corrugated flute direction every 6–8 in of stacked cardboard. This interlocks fibers, resisting collapse and improving forklift stability.

5. Palletizing Cardboard Bales

Palletizing simplifies forklift handling, sorting, and staging for transportation.

5.1 Pallet Selection

Use heavy-duty, kiln-dried pallets rated for at least 2,500 lb. Size pallets to match bale footprint, typically 40” × 48”.

5.2 Positioning the Bale

- Center the bale on the pallet, leaving 1–2 in clearance on all sides.

- If stacking bales, ensure each lower bale is strapped securely and the top surface is flat.

- When double-stacking, use cardboard slip sheets or thin plywood between bales to distribute weight evenly.

5.3 Securing to the Pallet

- Stretch Wrap: Wrap the entire pallet and bale assembly with 3–4 passes of 80–100% pre-stretched film.

- Strapping Through Pallet: Run strapping over the top of the bale, under the pallet deck boards, and back over the top. Tension and seal.

6. Baling Cardboard at Retail Locations (e.g., Walmart)

Large retailers often use on-site balers, but in locations without balers, managers can implement the manual methods above. Key considerations:

- Safety Training: Employees must follow lock-out/tag-out procedures when using jigs or pallet jacks for compression.

- Space Planning: Dedicate a clean, dry area near receiving docks for baling operations.

- Recycling Contracts: Coordinate with local recyclers on bale specifications and pickup schedules to optimize load consolidation.

7. Tips for Effective Cardboard Baling

- Regular Maintenance: Inspect manual frames, tensioners, and pallet jacks for wear and safety.

- Moisture Control: Store cardboard indoors or under cover; wet paper loses structural integrity and fetches lower recycling value.

- Record Keeping: Track bale weights and pickup dates to analyze recycling volumes and cost savings.

- Alternative Binding: For low-volume streams, consider heavy-duty zip ties or reusable hook-and-loop straps.

8. Troubleshooting Common Issues

| Issue | Cause | Solution |

|---|---|---|

| Low bale density | Inadequate flattening or compression | Break boxes smaller; increase compression force |

| Straps cutting into bale | Overtensioning with thin straps | Use wider straps; add corner protectors |

| Bale bulging on sides | Uneven stacking, missing diagonal straps | Re-strap with full pattern; restack layers |

| Moisture absorption | Outdoor exposure, humidity | Move baling area indoors; cover stockpile |

| Strapping tool jams | Dirty or worn tensioner | Clean, lubricate, or replace tool regularly |

Conclusion

Baling cardboard streamlines recycling, conserves warehouse space, and reduces handling costs. While industrial balers offer rapid, high-volume compression, manual methods using framing jigs, pallet jacks, and leverage tools enable smaller operators to produce quality bales. Proper preparation—sorting, flattening, layering—and secure strapping or wiring ensure bale integrity. Palletizing enhances safety and compatibility with forklifts. By applying these practices, businesses of any size can implement an efficient cardboard baling process that benefits both operations and the environment.

Leave a Reply