The weight and size of a bale of cardboard vary widely depending on the baling equipment, bale type, compaction ratio, moisture content, and intended use. Understanding these variables is essential for logistics, recycling efficiency, space planning, and revenue optimization. Below is an in-depth exploration, covering:

- Bale classifications

- Typical weight ranges

- Standard bale dimensions

- Factors influencing weight and size

- Equipment types and their outputs

- Compaction ratios and density

- Practical considerations for handling, transport, and sale

1. Bale Classifications

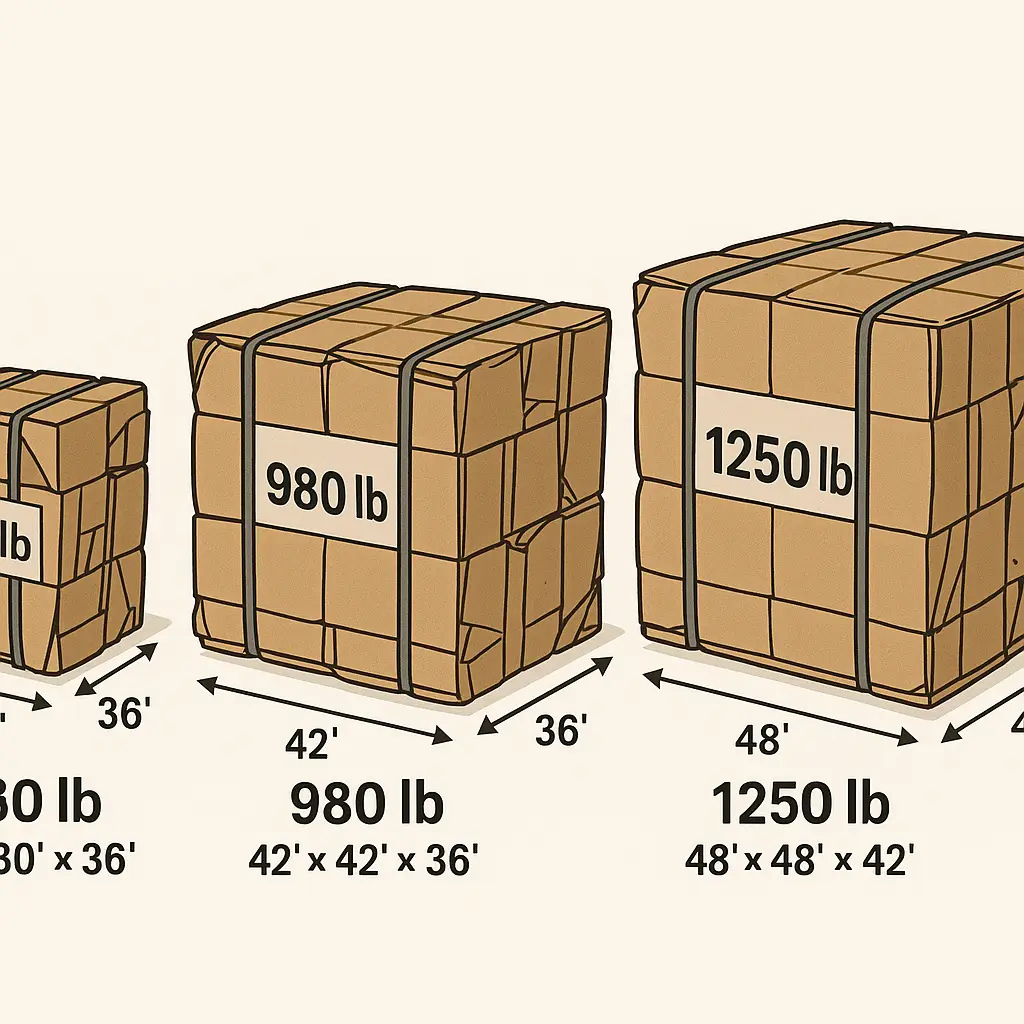

Cardboard bales are generally grouped into three categories based on their weight and size:

- Small bales: Produced by light-duty or mini balers

- Medium bales: Often from vertical “mill-size” balers

- Large bales: From heavy-duty or horizontal balers

Each category serves different volumes of cardboard generation—from small retail outlets to large industrial facilities.

2. Typical Weight Ranges

Weight varies significantly from one bale type to another:

- Small Bales

- 30–80 kg (67–176 lb)

- Some mini balers yield 30–70 kg bales

- Medium (Mill-Size) Bales

- 300 kg (660 lb) medium bale from vertical baler (120×80×80 cm)

- 400–500 kg (880–1,100 lb) mill-size bale: 1.2 m ×1.0 m ×0.8 m

- 400–450 kg for “BaleTainer®” auto-load baler

- Large Bales

- 500–600 kg (1,100–1,300 lb) from heavy-duty vertical balers

- 800–1,000 lb (360–450 kg) common mill-size recommendation

- Up to 1,100 lb (500 kg) with highest-density machines

- Industrial horizontal balers can hit 1,750–2,222 lb (800–1,000 kg)

These weight ranges reflect machine capacity, bale density, and operator settings.

3. Standard Bale Dimensions

While weights vary, several dimensional standards have emerged:

| Bale Type | Length | Width | Height | Notes |

|---|---|---|---|---|

| Small vertical | 60 cm | 40 cm | 20–50 cm | Mini balers |

| Medium vertical | 120 cm | 80 cm | 80–100 cm | 47.2×31.5×31.5 in (120×80×80 cm) |

| Mill-size vertical | 120 cm | 100 cm | 80 cm | 400 kg minimum standard |

| Standard vertical | 30″×48″×60″ | — | — | 50 ft³; up to 900 lb/409 kg |

| Horizontal large | Variable up to 2 m | Variable | Variable | 1,750–2,222 lb |

Dimensions depend on machine throat size and tie-off locations; end-users often specify ideal dimensions for truck loading.

4. Key Factors Influencing Weight and Size

Several variables impact the final bale characteristics:

- Compaction Force: Higher tonnage yields denser, heavier bales.

- Moisture Content: Wet cardboard weighs more but is unsellable; must stay dry.

- Cardboard Type: Corrugated (OCC) is denser than paperboard.

- Tie Method: Wire-tied mill-size bales support higher weight than tape-bound ones.

- Baler Mechanism: Internal press vs. external cylinders affect bale shape and weight.

Understanding these factors helps tailor bale specifications to recycling markets’ requirements.

5. Equipment Types and Outputs

5.1 Vertical Balers

- Mini Balers: 3–4 ton compaction; 30–70 kg bales; footprint <1 m²

- Light-Duty: 10–20 ton compaction; 80–250 kg bales; low cycle times (~30 s)

- Mill-Size: 50 ton compaction; 400–600 kg bales; standard 30″×48″×60″ bales

- Heavy-Duty: 50–60 ton compaction; up to 700 kg bales; includes Orwak 3500

5.2 Horizontal Balers

- Dual-Ram Balers: Produce bales >500 kg; ideal for very high volumes.

- GigaBaler: 500–550 kg payload bales for maximum transport rebates.

Horizontal machines require more floor space and higher capital but yield large, uniform bales.

6. Compaction Ratios and Density

- Typical Volume Reduction: 5:1 to 10:1 (Loose to baled)

- Loose Cardboard Density: ~80 kg/m³ (135 lb/yd³)

- Baled Cardboard Density: 200–600 kg/m³ depending on machine and settings

Higher density improves transport efficiency but may demand stronger baler structures and heavier tie wires.

7. Practical Considerations

7.1 Transport and Handling

- Weight Limits: Trucks/divers must not exceed legal axle loads; ideal bale <1,000 lb if using smaller forklifts.

- Storage: Under cover to avoid moisture; wet bales lose recyclability and value.

7.2 Recycling Value

- Rebate Rates: Tied to bale weight and quality; mill-size bales (~400 kg+) yield best rates.

- Market Fluctuations: Cardboard prices vary (£50–£150/tonne in 2022–2024).

7.3 Operational Efficiency

- Cycle Time: 30–60 s per bale; throughput matters for large generators.

- Labor: Vertical balers require manual feeding; automatic solutions recover 2,000–4,000 staff hours/year.

- Footprint: Mini balers need ~1 m²; horizontal systems require >10 m² plus conveyor feeds.

Conclusion

A cardboard bale’s weight spans from 30 kg in mini systems to over 1,000 kg in industrial horizontal balers. Dimensions vary, but “mill-size” (120×100×80 cm) remains the most widely accepted standard for recyclers, requiring a minimum 400 kg weight. Selecting the right baler involves balancing available space, labor capacity, cardboard volume, and desired bale specifications to maximize recycling rebates and minimize handling costs.

Leave a Reply