Key Takeaway: A standard 53 ft × 8.5 ft semi-trailer can hold between 60 and 117 common cardboard bales, depending on bale dimensions and stacking height. Flatbed trailers of the same footprint accommodate similar bale counts but require secure strapping and weather protection.

(more…)Category: Cardboard

-

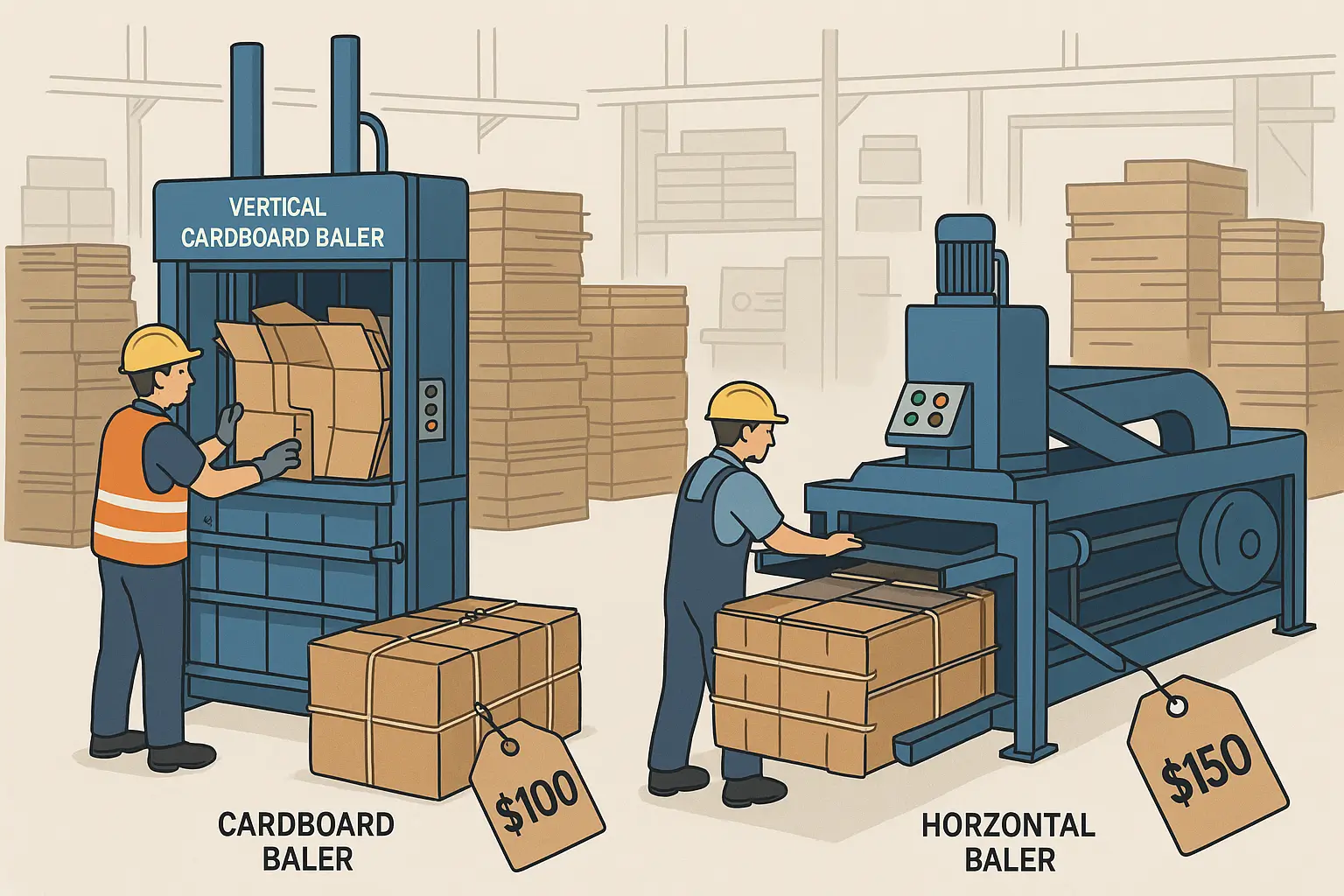

Cardboard Baler Cost Analysis and Pricing Guide

Main Takeaway: Investing in a cardboard baler typically requires an upfront expense ranging from approximately $3,000 for basic vertical models to over $100,000 for fully automated, high-capacity horizontal balers. The optimal choice hinges on waste volume, available space, budget, and desired level of automation—balancing initial purchase price against long-term operational savings.

(more…) -

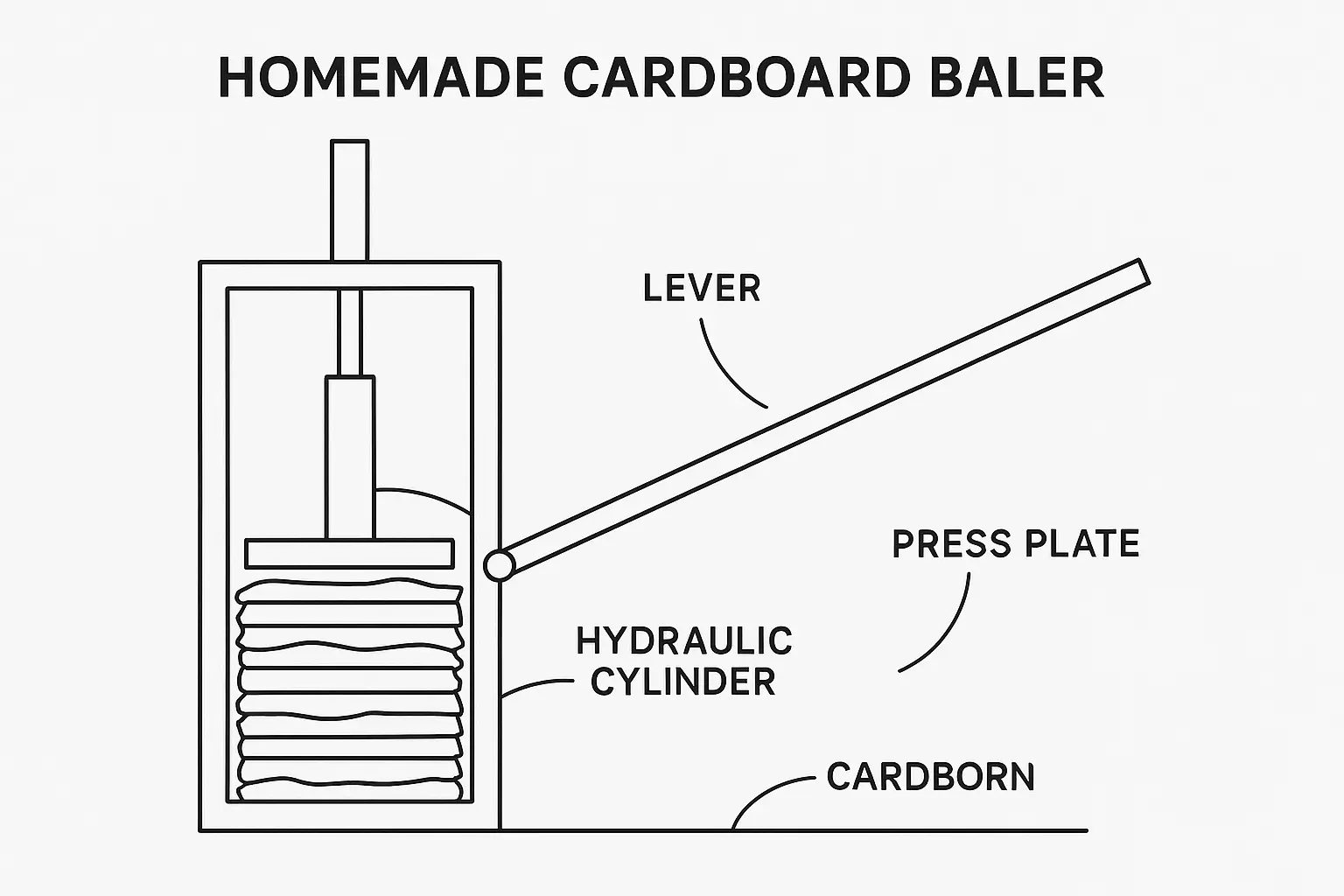

Comprehensive Guide to Building a Homemade Cardboard Baler

Key Takeaway: Constructing a DIY cardboard baler is an achievable project that can dramatically reduce waste volume, streamline recycling, and save costs. By carefully selecting materials, tools, and a suitable design—whether manual, hydraulic, or mechanical—you can build a safe, efficient baler tailored to your needs.

(more…) -

How to Move a Cardboard Baler

Moving a cardboard baler is a complex task that demands meticulous planning, careful preparation, proper equipment, and attention to safety. Cardboard balers are heavy, bulky machines used in recycling facilities, warehouses, retail stores, and manufacturing plants to compress and bind cardboard waste into manageable bales. Whether you’re relocating a baler within the same facility, installing it at a new site, or reconfiguring your production line, this guide will walk you through each step required to move a cardboard baler safely and efficiently.

(more…)