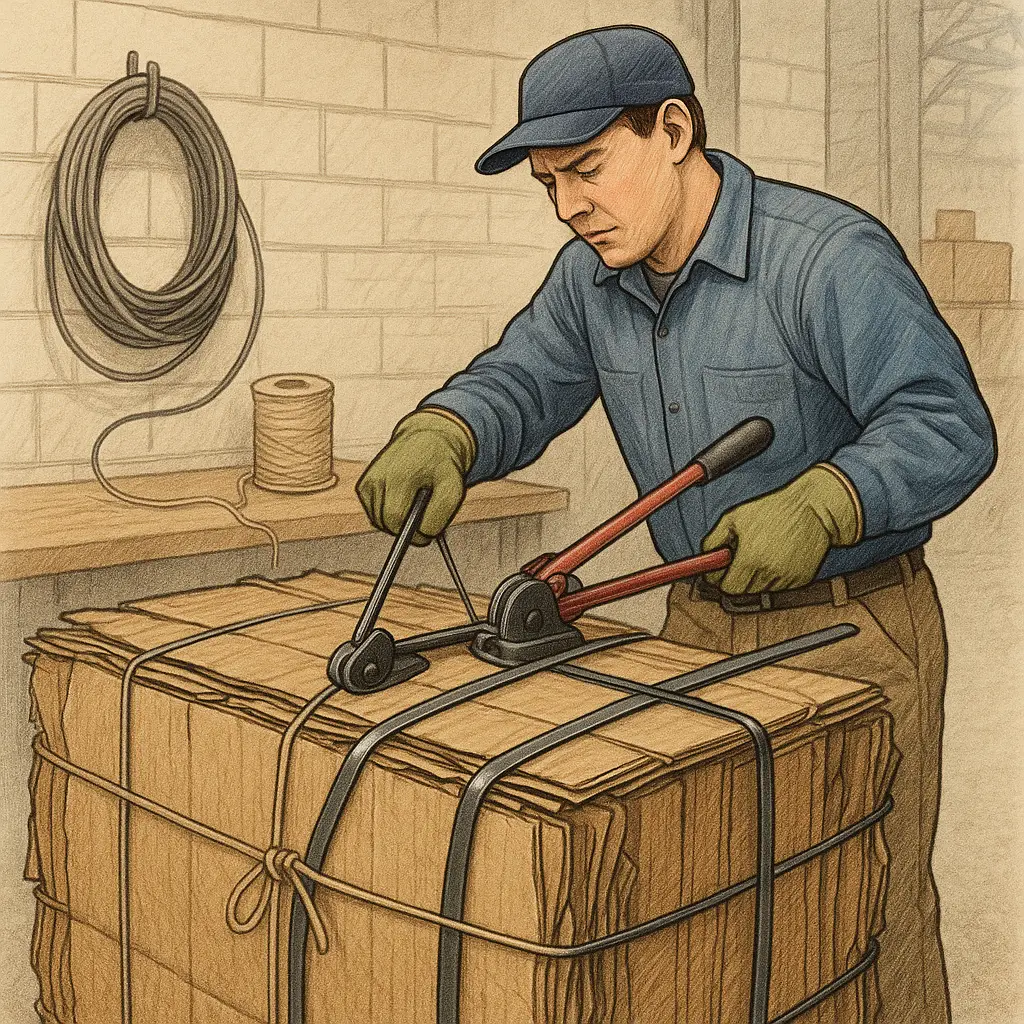

Main Takeaway: Securing a cardboard bale correctly is essential for safe handling, storage, and transportation. Whether using baling wire, polypropylene twine, or steel strapping, following structured preparation, tying, and finishing steps will ensure the bale remains intact and manageable.

(more…)Category: Cardboard

-

Guide to Resetting, Operating, and Repairing a Cardboard Baler

Key Takeaway: Properly resetting, operating, and maintaining a cardboard baler requires a clear understanding of its hydraulic and electrical systems, adherence to safety protocols, and systematic troubleshooting. Regular inspections and preventive maintenance will drastically reduce downtime and extend equipment life.

(more…) -

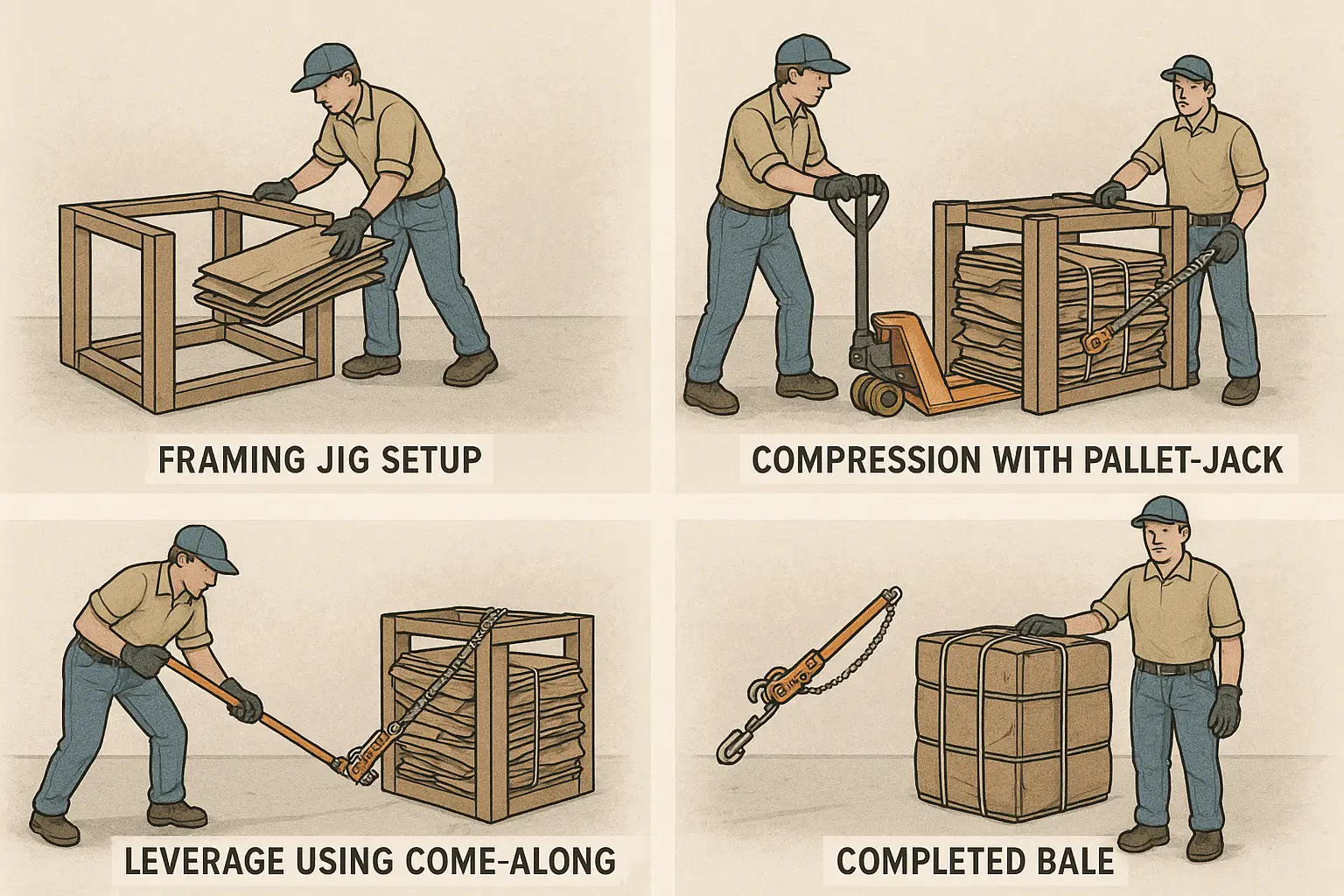

Guide to Baling Cardboard for Recycling and Storage

Efficiently baling cardboard is essential for any business, warehouse, retail outlet, or large-scale recycling operation. Well-formed bales save space, streamline handling, and improve the economics of recycling by reducing transportation costs. This guide covers everything from DIY methods to semi-automated processes, addressing how to bale cardboard without a baler, how to construct corrugated cardboard bales, how to tie and palletize bales, and tips specific to common settings such as retail stores and distribution centers.

(more…) -

Guide to Efficient Cardboard Baling

Key Takeaway: Proper operation and maintenance of a cardboard baler optimize throughput, safety, and equipment longevity. Monitor fill indicators, follow safe removal and changeover procedures, and adopt efficient loading techniques to maintain production flow. Most balers complete a full bale cycle in 2–5 minutes, depending on model and operator efficiency.

(more…) -

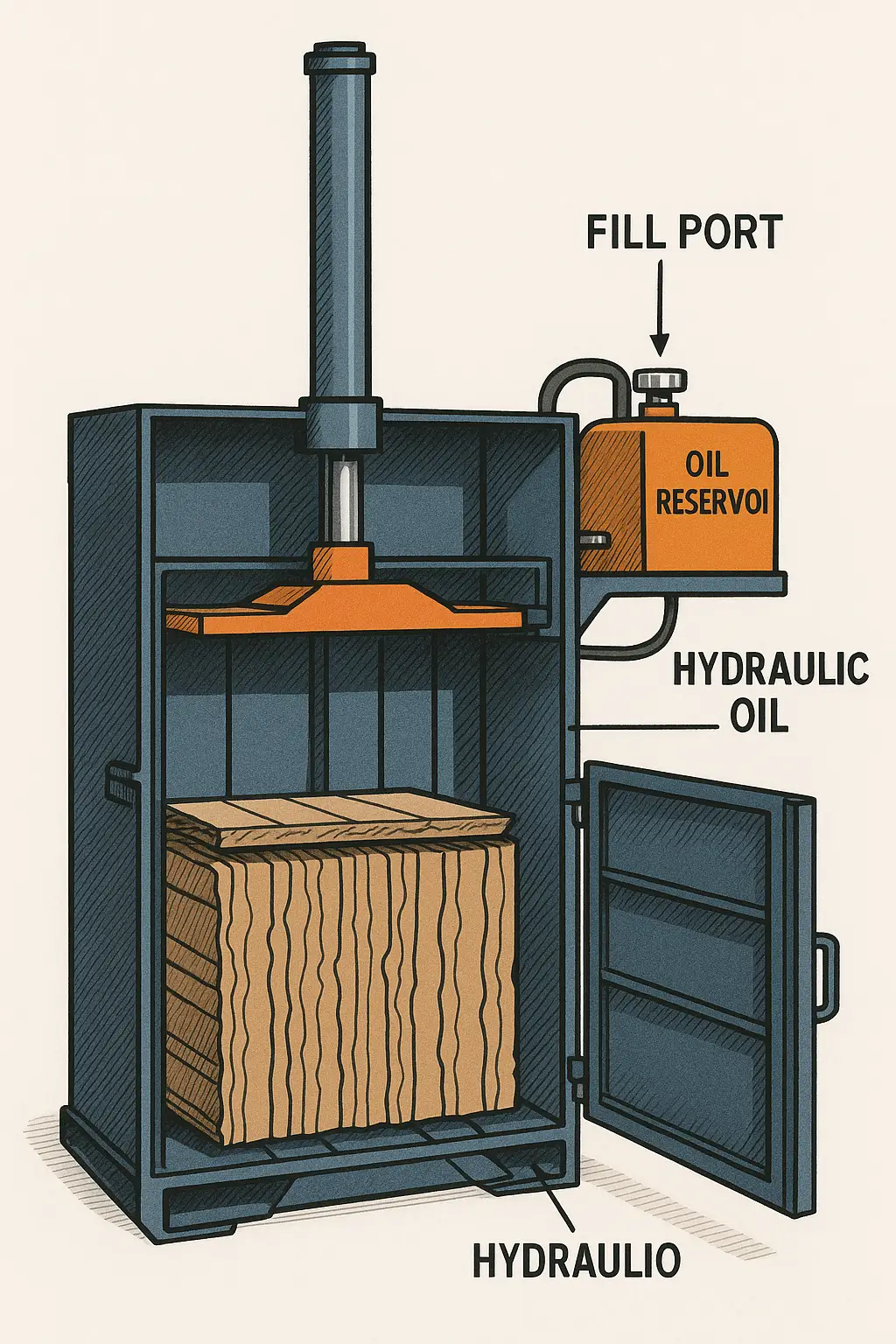

Cardboard Baler Hydraulic Oil: Capacity, Type, and Consumption

Key Takeaways: A standard vertical cardboard baler holds between 18 and 30 gallons of hydraulic oil in its reservoir. Most manufacturers recommend anti-wear, all-weather hydraulic oils in viscosity grades ISO 32, ISO 46, or AW 68, chosen based on ambient temperature and duty cycle. Routine oil changes are typically performed every 1,000–2,000 operating hours (or annually), and unaddressed leaks can cause annual oil consumption to exceed 100 gallons per machine.

(more…) -

Cardboard Bale Value: Analysis and Market Overview

Key Takeaway: A standard cardboard bale, weighing between 800 and 1,000 lbs (0.4–0.5 ton), is currently worth approximately $20 to $95 per bale in the U.S. market—equating to $40–$190 per ton—with prices influenced by regional demand, bale quality, market trends, and transportation costs. Understanding these factors is essential for maximizing revenue from cardboard recycling and optimizing waste-management strategies.

(more…) -

Market Value of Baled Cardboard Today

Main Takeaway: Baled cardboard is a modestly valued commodity whose price fluctuates with fiber markets, supply–demand dynamics, bale quality, and regional factors. As of August 2025, U.S. scrap‐yard prices average about $66.67 per ton, yielding roughly $22 per 660 lb bale. Prices can range from $40 to $95 per ton (≈$13–$31 per bale), while U.K. rates span £50–£150 per ton. Understanding these ranges, bale weights, quality grades, and timing can help sellers and buyers optimize revenue and costs.

(more…) -

Cardboard Bale Costs: An In-Depth Analysis

Key Takeaway: The cost of a bale of cardboard varies widely—from approximately $20 to $300 per metric ton (equating to $6–$90 per typical 300–900 kg bale)—depending on geography, bale weight and dimensions, material quality, market demand, and logistical factors. Understanding these variables enables businesses and recyclers to optimize revenue, reduce waste-management expenses, and capitalize on recycling markets.

(more…) -

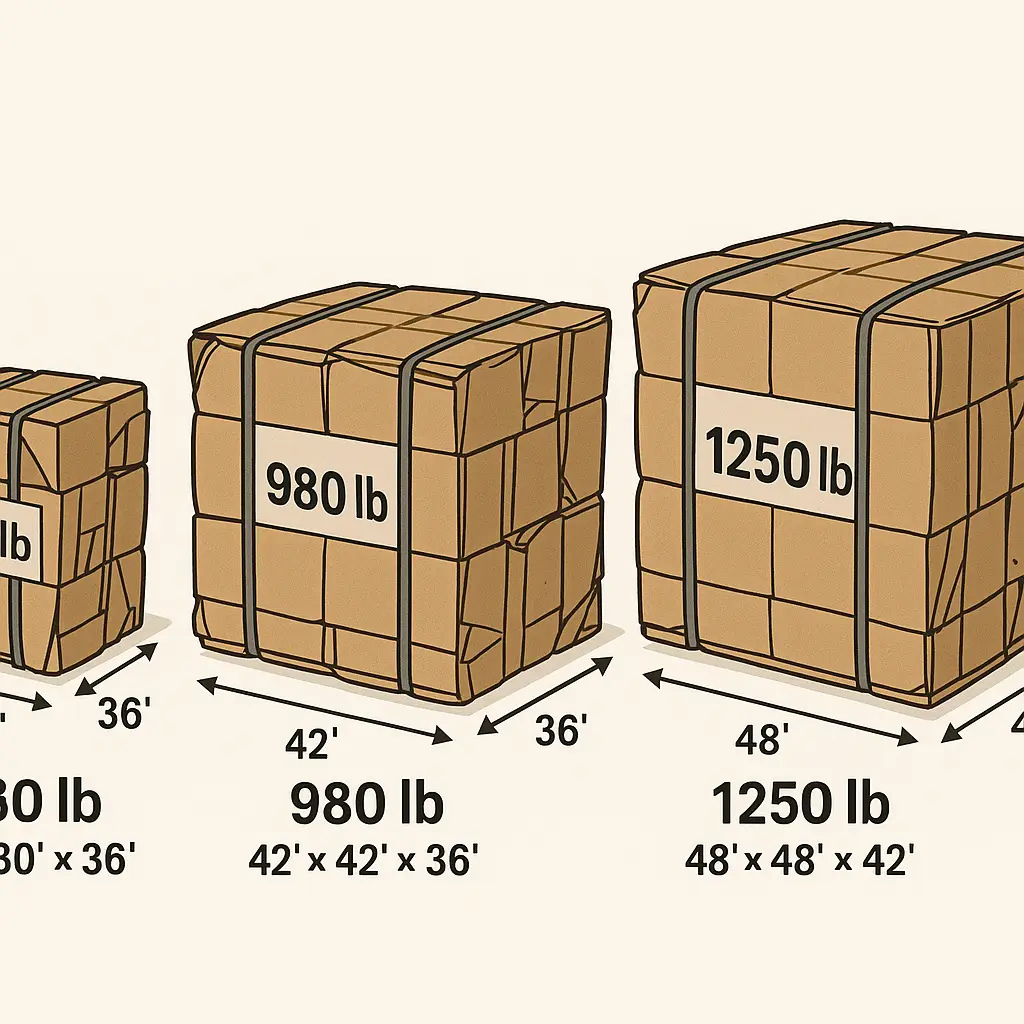

Comprehensive Analysis of Cardboard Bale Weight and Size

The weight and size of a bale of cardboard vary widely depending on the baling equipment, bale type, compaction ratio, moisture content, and intended use. Understanding these variables is essential for logistics, recycling efficiency, space planning, and revenue optimization. Below is an in-depth exploration, covering:

(more…) -

Maximizing Revenue from Cardboard Bales

Key Takeaway In today’s fluctuating recycling markets, sellers can expect to receive anywhere from $40 to $120 per ton of baled corrugated cardboard under typical conditions, with occasional extremes ranging from $20 up to $210 per ton based on regional demand, bale quality, and prevailing commodity prices. Achieving top-dollar requires producing mill‐size bales, maintaining high material quality, and timing sales to market peaks.

(more…)