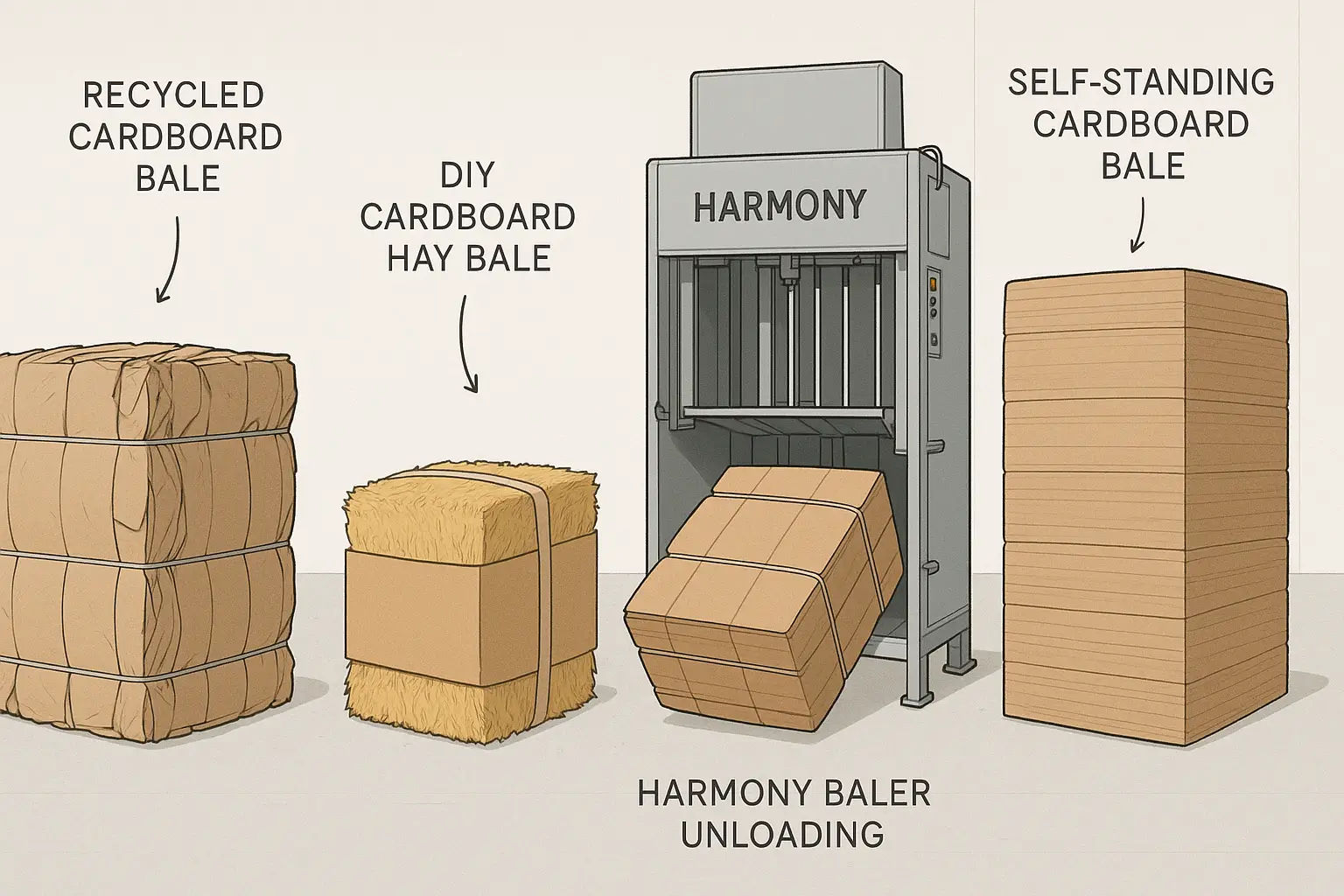

Key Takeaway: Cardboard bales, whether generated by retail giants like Walmart or repurposed into decorative “hay bales,” can be efficiently managed through established recycling and processing systems. Additionally, with the right tools and techniques, cardboard can be transformed into stable, upright structures resembling hay bales and safely unloaded from baling equipment such as the Harmony cardboard baler.

1. Walmart’s Management of Cardboard Bales

Retailers like Walmart generate vast quantities of cardboard from shipping, merchandise packaging, and returns. To handle this volume sustainably, Walmart employs a multi-step process:

1.1 Collection and Pre-Sorting

In each store, cardboard boxes are flattened and placed in dedicated recycling areas. Employees are trained to remove contaminants (plastic liners, foam inserts, tape) to ensure the cardboard remains clean and recyclable.

1.2 Baling

Clean cardboard is loaded into industrial balers—typically horizontal or vertical machines that compress large volumes of corrugated fiberboard into dense bales. Each bale measures approximately 48” × 30” × 40” and weighs between 1,000 and 1,200 pounds. Balers use hydraulic pressure to reduce the volume by up to 90%, facilitating transport and storage.

1.3 Storage and Pickup

Baled cardboard is stored in secure, weatherproof areas to prevent water damage. Walmart coordinates with local recycling haulers under long-term contracts. Haulers collect bales on a scheduled basis—often weekly for large stores—using roll-off trucks equipped with hydraulic lifts.

1.4 Recycling and Repulping

Once transported to a recycling facility, cardboard bales are shredded, mixed with water, and pulped. Contaminants are screened out, and the resulting fiber slurry is reformed into new paperboard or containerboard. This closed-loop system reduces raw material consumption and landfill waste.

Environmental Impact:

- Diverting over 90% of cardboard from landfills

- Reducing greenhouse gas emissions by lowering virgin fiber production

- Enabling large-scale material recovery through economies of scale

2. Crafting “Hay Bales” from Cardboard

Creating decorative hay-style bales from cardboard is an ingenious DIY project suitable for seasonal displays, theatrical sets, or rustic décor. The process involves shaping and finishing cardboard to mimic the texture and appearance of straw bales.

2.1 Materials and Tools Needed

- Corrugated cardboard sheets (large, double-wall preferred for rigidity)

- Utility knife or box cutter

- Hot glue gun and glue sticks

- Jute twine or raffia (natural fiber for tying)

- Acrylic paint: golden yellow, light brown, and dry brushing white

- Wire cutters (for reinforcing wire, optional)

- Staple gun and staples

2.2 Constructing the Bale Core

- Layering: Stack 4–6 large cardboard sections in alternating corrugation directions (vertical/horizontal) for strength.

- Gluing: Hot-glue perimeter edges between layers to prevent shifting. Apply glue in a zigzag pattern approximately 4” apart.

- Clamping: Use heavy books or temporary straps to compress layers until dry (about 5–10 minutes per side).

2.3 Shaping and Detailing

- Beveling Edges: Use a utility knife to slice off sharp corners and create a slightly rounded edge reminiscent of compressed straw.

- Surface Texture: Lightly score the surface with shallow, parallel cuts (¼” deep) to simulate compressed straws. Vary spacing to avoid uniformity.

- Reinforcement (Optional): Insert thin metal wires (cut with wire cutters) into the scored lines for extra rigidity in high-traffic displays.

2.4 Tying and Finishing

- Twine Straps: Wrap jute twine around the bale twice lengthwise and twice widthwise, securing with staples or a simple knot. This imitates the binding wires of real straw bales.

- Painting:

- Base coat with golden yellow acrylic.

- Dry brush light brown on raised edges for depth.

- Highlight random sections with white dry brushing to evoke sun-bleached straw.

- Sealing (Optional): Spray with clear matte sealant to protect against moisture and abrasion.

Applications:

- Wedding and event décor

- Theatrical and film set dressing

- Window displays in retail stores

- Educational props for farm-themed exhibits

3. Unloading Cardboard from a Harmony Baler

The Harmony series of vertical cardboard balers is widely used in retail and light-industrial settings. Safe and efficient unloading requires adherence to manufacturer guidelines and proper technique.

3.1 Pre-Unloading Safety Checks

- Power Off & Lockout: Ensure the baler is switched off and locked out according to OSHA standards. Verify gauge reads zero pressure on hydraulic system.

- PPE: Operators must wear cut-resistant gloves, steel-toed boots, and safety glasses.

3.2 Operating Sequence

- Open Door Latch: Pull the built-in lever to release the front door latch. The door typically pivots outward and downward, providing access to the bale chamber.

- Lower Pressure Plate: On most Harmony models, manually release the pressure plate lock pin. The hydraulics will slowly lower the ram, compressing the bale incrementally toward chute height.

- Remove Bale: Once the ram is fully retracted, the bale rests on the door lip. Use a pallet jack or forklift to slide under the pallet (if attached) or hook bale lifter bars into the pre-drilled bale slots.

- Close and Reset: After bale removal, lift the ram back to the start position either manually or with low-pressure hydraulic assist. Reinsert the locking pin and close the door, ensuring the door sensor confirms a secure seal.

3.3 Troubleshooting Common Issues

- Door Not Latching: Inspect latch mechanism for debris. Lubricate hinges and latches quarterly.

- Hydraulics Slow: Check hydraulic fluid levels; top up with manufacturer-recommended oil. Bleed air from the system if spongy behavior persists.

- Uneven Bale Shape: Occurs when cardboard feed is off-center. Train operators to distribute cardboard evenly across the chamber.

4. Building a Self-Standing Cardboard “Hay Bale” Sculpture

Beyond small decorative bales, one can craft large-scale, freestanding hay bale replicas from cardboard for dramatic visual impact in retail displays, expos, or agricultural-themed events.

4.1 Structural Framework

- Skeleton Construction: Weld or bolt a lightweight steel or PVC frame shaped as a rectangular prism (typ. 4’ × 3’ × 2’) to support the cardboard skin.

- Base Support: Attach the frame to a wooden or metal base plate with adjustable leveling feet to accommodate uneven floors.

4.2 Cardboard Cladding

- Skin Panels: Cut single-wall cardboard to panel sizes that fully cover each face of the frame. Score fold lines for crisp edges.

- Attachment: Secure panels to the frame using self-tapping screws with large washers or heavy-duty zip ties through pre-drilled holes.

4.3 Texturing and Binding Illusion

- Surface Scoring: Similar to section 2.3, employ a utility knife to score shallow grooves in horizontal bands. Vary depth and spacing to mimic straw compaction.

- Fiber Overlay: Glue short lengths of raffia or thin wood shavings along scored lines to add three-dimensional straw texture.

- Binding Ropes: Wrap thick jute ropes at intervals and attach to the base or frame with discreet eyehooks, creating the impression of bound hay bales.

4.4 Achieving Upright Stability

- Center of Gravity: Position heavier materials (e.g., MDF board or small sandbags) towards the bottom inside the frame to lower the center of gravity.

- Wide Footprint: Extend the base plate beyond the bale footprint by at least 6” on each side, then cover the extension with decorative grass matting or “hay” to conceal.

- Wind Resistance (for outdoor use): Anchor the base to ground stakes or sandbag weights if the display is subject to drafts.

Conclusion

From Walmart’s streamlined recycling operations to creative DIY projects and industrial baler handling, cardboard bales serve both functional and aesthetic purposes. Large retailers maximize sustainability by baling and repulping cardboard, while hobbyists and professionals alike can repurpose cardboard into convincing hay bale replicas. When working with balers such as the Harmony series, adherence to safety protocols ensures efficient unloading. Finally, by combining structural framing, texturing techniques, and stability measures, cardboard can support impressive, upright “hay bales” suitable for a variety of display environments.

Leave a Reply