Key Takeaways: A standard vertical cardboard baler holds between 18 and 30 gallons of hydraulic oil in its reservoir. Most manufacturers recommend anti-wear, all-weather hydraulic oils in viscosity grades ISO 32, ISO 46, or AW 68, chosen based on ambient temperature and duty cycle. Routine oil changes are typically performed every 1,000–2,000 operating hours (or annually), and unaddressed leaks can cause annual oil consumption to exceed 100 gallons per machine.

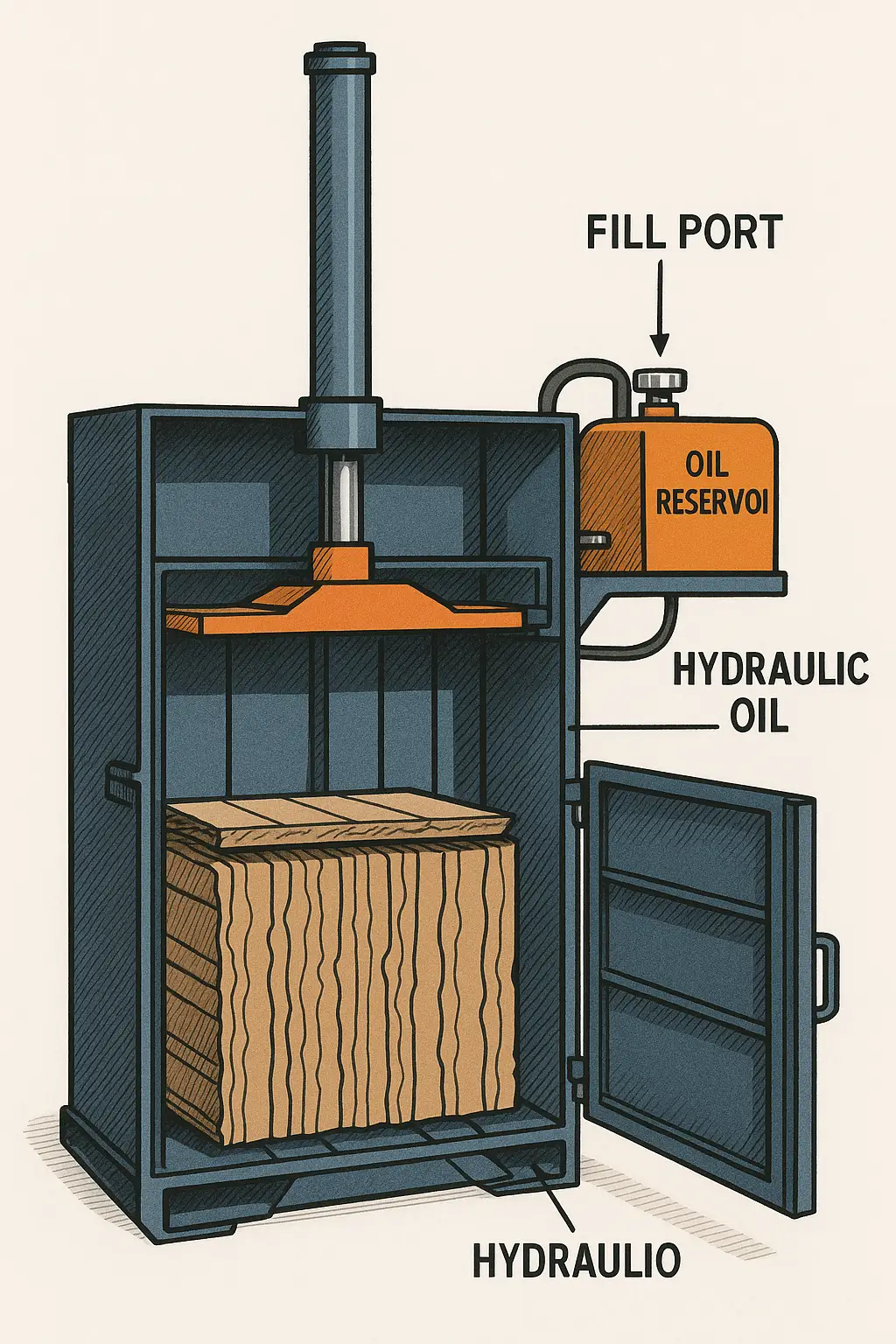

1. Hydraulic Oil Reservoir Capacity

The amount of hydraulic oil a cardboard baler reservoir holds varies by model and manufacturer. Two representative examples:

Model

Reservoir Capacity

Standard 60″ Vertical Baler (WasteCare 60-1048)

30 gallons SELCO V5-HD Vertical Baler

18 gallons

Moreover, data compiled across multiple baler lines (see Cram-A-Lot PDF specifications) shows smaller units may hold as little as 11 gallons, while larger high-density machines also typically top out at 30 gallons.

Thus, most industrial cardboard balers feature a reservoir size in the 18–30 gallon range.

2. Recommended Hydraulic Oil Types

Selecting the correct hydraulic fluid is critical for baler performance, longevity, and energy efficiency. Key oil properties and typical grades:

Property

Requirement

Base oil

Petroleum-based anti-wear (Group II or III) Viscosity grade

ISO 32, ISO 46, or AW 68 (see temperature guidance below) Viscosity Index

≥ 100–105 to maintain stable viscosity over temperature range Additives

Oxidation inhibitor, anti-rust, anti-foam, de-aerator

Common Viscosity Grades

Viscosity Grade

Flow Characteristics

Recommended Ambient Range

ISO 32 (HVLP 22)

Thin, fast flow

−20 °C to +40 °C ISO 46

Moderate thickness

−15 °C to +60 °C AW 68

Thicker for heat resistance

Above +40 °C

- DIN 51524-T3 / HVLP 22 (ISO 32) is often specified for temperate conditions and rapid flow.

- ISO 46 balances pump protection and flow in warm environments.

- AW 68 (equivalent ISO 68) suits high-temperature operations above 40 °C.

Major brand recommendations include Shell, Mobil, Total, BP, AMSOIL, and specialized formulations like Hydrex AW68 used by International Baler Corp.

Note: Use of naphthenic or “rust & oxidation” (R&O) oils voids many manufacturers’ warranties.

3. Hydraulic Oil Consumption and Change Intervals

3.1 Scheduled Oil Changes

To maintain system cleanliness and performance, hydraulic oil should be changed every 1,000–2,000 operating hours, or at least annually, whichever comes first. Steps typically include:

- Position ram in starting position

- Power down and unplug machine

- Remove vent filter

- Extract old oil via suction pump

- Clean reservoir if severely contaminated

- Refill to “Best Oil Level” line and replace filter

3.2 Unscheduled Top-Ups and Leak Losses

Even well-maintained balers can lose oil through minor leaks, gasket seepage, or maintenance top-ups. Reported annual leak losses range:

- A single baler may lose 100–200 gallons per year if leaks go unaddressed.

- At current market prices (~$10–$15 per gallon), leaks alone can cost $1,000–$3,000+ annually.

Implementing hydraulic manifolds, cartridge valves, and routine seal replacements can reduce leak-related consumption by 50–80%.

4. Impact of Oil Selection and Maintenance

4.1 Performance and Efficiency

- Correct viscosity ensures pumps and valves operate at optimal pressures, reducing cycle time variability.

- Anti-wear additives prolong component life, reducing downtime and repair costs.

- High viscosity index oils maintain stable flow characteristics, minimizing energy losses in hot or cold conditions.

4.2 Energy Consumption

Hydraulic systems waste up to 20% of energy through idling and mismatched pressures. Selecting a fluid with appropriate viscosity and performing regular oil analysis can:

- Reduce pump energy draw by 10–15%

- Lower system heating and related cooling requirements

- Extend hydraulic pump and cylinder service intervals by 30–50%

5. Best Practices for Hydraulic Oil Management

- Monitor oil levels weekly, topping up before levels fall below the “Min Oil Level” marker.

- Analyze oil condition every 500 hours via particle count and viscosity checks; look for water ingress and oxidation byproducts.

- Seal integrity inspections quarterly to identify potential leaks before they escalate.

- Keep ambient temperatures within recommended ranges (0–60 °C) or adjust oil grade accordingly.

- Use OEM-approved or equivalent oils to preserve warranty coverage and performance guarantees.

Conclusion

A cardboard baler’s hydraulic reservoir generally holds 18–30 gallons of anti-wear, all-weather hydraulic fluid, most often in ISO 32, ISO 46, or AW 68 grades, selected based on ambient conditions. Proper oil change intervals (every 1,000–2,000 hours) and vigilant leak management prevent excessive consumption—keeping annual fluid usage under 100 gallons and controlling operating costs. Adhering to these practices ensures efficient, reliable, and long-lived baler operation.

Leave a Reply